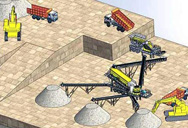

poudre de fer jeu à vendre POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- groupe de chats de carriere

- procédé de broyage de farine de silice

- mammut concasseur pour le ciment

- equipements de la fusion de l'or portable

- utilisez broyeur de barytine aux etats unis ou au mexique

- quels sont les inconvenients de concasseurs mobiles

- structure du concasseur à percussion

- rouleau vertical de ciment de la technologie de lusine lm serie

- chinoise de haute energie de broyage

- matériel de concassage de roches en Nouvelle Caldonia

- les eaux de lavage de filtres Indonésie sable

- les mines d'or en afrique du Sud pour les enfants

- broyeurs à boulets à vendre en afrique

- les mâchoires du tyrannosaure

- reymond mill ball mill vs

installation de concassage indien 120 tph

The difference between raymond mill and ball mill - NEWS

2023.12.18 Comparison of Raymond Mill vs Ball Mill. Raymond mill is a type of grinder for grinding various materials. It has two rotating discs with sharp edges. The

Read More

What's the Differences Between Raymond Mill and

2018.10.17 The most obvious difference is that the particle size of products produced by Raymond mill is much finer than ball mill's. Here, Xinhai will explain the specific differences between...

Read More

What’s the Differences Between Raymond Mill and Ball Mill?

2018.10.17 Both Raymond mill and ball mill are the common grinding equipment, but there are many differences between them. The most obvious difference is that the

Read More

Raymond Mill, Ball Mill, Which One Is Better?

2023.6.15 In fact, the biggest difference between the use of Raymond mill and ball mill is that the area of the ball mill is larger than that of Raymond mill, and the price will

Read More

ball mill and raymond mill - Zhongde Heavy

2022.7.29 The ball mill is more suitable for coarse grinding of materials, and the Raymond mill is more suitable for fine grinding of materials. Working Principle In the operation of the ball mill, it mainly

Read More

The difference between Raymond mill and ball mill-SBM

2023.3.20 Although Raymond mills and ball mills can grind materials and process them into fine powder materials, these two devices also have different essential

Read More

What Is The Difference Between Raymond Mill

There are mainly four parts: First, the output of Raymond Mill and Ball Mill. Output of Raymond Mill is 30t/h, however the output of Ball Mill is 200t/h. So, as you can see, output of Raymond Mill is smaller than Ball Mill.

Read More

Raymond® Roller Mill air-swept vertical ring-roll - Schenck

The Raymond ® Roller Mill is an air-swept vertical ring-roll mill with an integral classification system that simultaneously dries, pulverizes and classifies a number of different types of

Read More

Raymond® Ball Mill or tube mill - Schenck Process

The Raymond® Ball Mill, also known as a tube mill, is designed for a wide variety of applications where hard, abrasive materials are ground to a required fineness.

Read More

球磨是干什么的,详解球磨工艺,解开我多.的疑惑!

2020.4.19 球磨方式 球磨机根据工作方式的不同,有干式球磨机和湿式球磨机之分,根据不同的行业以及物料的特性使用不同的球磨方式。干式球磨是直接将物料输送到磨机内,通过磨机的旋转靠钢球的冲击力将原

Read More

fr/broyeur à boulets vs raymond mill.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

Ball Mills - 911 Metallurgist

2017.2.13 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume.

Read More

搅拌磨与球磨磨矿对比试验 - neu.cn

2015.12.9 搅拌磨与球磨磨矿对比试验. 李艳军1, 郭旺1, 王绍兴2, 刘雁玲3. 摘要 :研究了搅拌磨和球磨磨矿产品的粒度特性及其磨矿过程中的比生产率、能耗情况.结果表明:搅拌磨磨矿产品较为均匀,球磨磨矿产品中微细粒和粗颗粒的质量分数较高;分别采用直线和指数 ...

Read More

Ball Mill - an overview ScienceDirect Topics

where d b.max is the maximum size of feed (mm); σ is compression strength (MPa); E is modulus of elasticity (MPa); ρb is density of material of balls (kg/m 3); D is inner diameter of the mill body (m).. Generally, a maximum allowed ball size is situated in the range from D /18 to D/24.. The degree of filling the mill with balls also influences productivity of the mill

Read More

Calcium Carbonate - SNG Microns Pvt Ltd

Raymond mill: In the grinding mill equipment, the production cost of Raymond mill is the lowest. Stereo structure save production line covers an area. Raymond grinding fineness is producing up-to 500 mesh size. Ball mill: A ball mill is a type of grinder used to grind and blend ore material into nano size using different sized balls. The ...

Read More

Raymond Mill Raymond Mill Working Principle - ZENITH

5 天之前 Under ideal working conditions, Raymond Mill consumes less energy than other ordinary grinding mills. For example, the MTM Medium-speed Grinding Mill only consumes 1.02kW/h when yielding a ton of materials and 1.48kW/h when feeding a ton of materials. Its electricity consumption is lower than that of ball mill at the same level by over 60%.

Read More

Pendulum Mill PM: Neuman Esser

The input quantities for the various mill sizes range from 0.5 t/h to 150 t/h. Our pendulum mill achieves high requirements for grain size distribution easily and extremely energy efficiently, even in case of the highest demands regarding the fineness to be achieved. The achievable upper particle sizes range from 10 μm to 1,000 μm.

Read More

What's the Differences Between Raymond Mill and Ball Mill?

2018.10.17 The most obvious difference is that the particle size of products produced by Raymond mill is much finer than ball mill's. Here, Xinhai will explain the specific differences between Raymond mill ...

Read More

Raymond® Mechanical Air Separator - Schenck Process

The separator may be used in combination with ball mills, tube mills and compartment mills. Its function is to maintain a constant fineness in the finished product. Open circuit In some cases, it is convenient to install the separator independently from the mill to make both a fine and coarse product simultaneously.

Read More

Energy-Efficient Technologies in Cement Grinding

2016.10.5 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Read More

What Is a Ball Mill? Blog Posts OneMonroe

2020.3.10 Overview of Ball Mills. As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material. It consists of a hollow compartment that rotates along a

Read More

Ball Milling in Organic Synthesis: Solutions and Challanges

2011.3.2 It is rather recommend changing reaction time than frequency. Start with 75-100% of the maximal operation frequency of the ball mill. The thermal stress for the reactants could be reduced by using cycled mode: mill for a. specific amount of time – 5-10 min pause – start milling again and repeat the procedure for the required amount of time.

Read More

Difference Between Sag Mill vs Ball Mill - Mech4study

1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill is used to grind the pieces of raw material into. powder-like structures. 3.

Read More

Modern Wet Milling and Material Processing 2012-11-01

2012.11.1 Traditional Wet Milling. The coatings industry is no different from others in its search for modern manufacturing techniques. The traditional high-speed dissolver, ball mill, vertical mill and standard horizontal mill have been the primary methods used to mill pigmented materials for more than 50 years, and are still considered to be the industry

Read More

Closed Circuit Grinding VS Open Circuit Grinding - 911

2016.10.12 Closed Circuit Grinding VS Open Circuit Grinding. The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This single-stage circuit is chiefly employed for coarse grinding when a product finer than 65 mesh is not required, but it can be ...

Read More

Producing Metal Powder from Machining Chips Using Ball

2023.6.27 A ball mill is additionally utilized to grind and combine materials, commonly with spherical or cylindrical-shaped grinding media such as balls or rods . Numerous researchers have effectively used ball milling to produce nanostructures of various materials or to investigate structural changes in materials during ball milling [87,88,89,90,91 ...

Read More

Ball Mill Ball Mills Wet Dry Grinding DOVE

3 天之前 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (0.3 TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabrication, DOVE Ball Mills as ...

Read More

(PDF) DESIGN AND OPERATION OF VERTIMILL®

2004.1.1 Abstract. A silver/lead/zinc mine in Queensland, Australia was originally designed to treat 1.5 million wet metric tonnes per annum. The original grinding circuit consisted only of primary ...

Read More

Bóng Mill Vs Ramond Mill

ball mill vs ramond mill World of Color Disney Wiki FANDOM powered by Jun 04, 2010 World of Color is a nighttime show at Disney California Adventure, part of 231 reviews of Opry Mills "This weekend I decided to travel a few hours away to Nashville for food

Read More

Ball Mill - RETSCH - powerful grinding and homogenization

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. Cooling, heating cryogenic grinding.

Read More

Autogenous Grinding Semi Autogenous Grinding Circuits

2017.7.20 ABC closed circuit, Autogenous-Ball-Mill-Crusher. Another similar technique is the ABC open circuit where the crusher product feeds the ball mill rather than the autogenous mill. Crusher product is typical feed to a ball mill using large diameter balls but not much grinding of 20-25 mm ore can be accomplished in an autogenous mill.

Read More

Grinding Media - Union Process

Alumina Balls and Satellites. Union Process is the one source for 90%, 94%, 99.5% and 99.9% alumina media. 90% alumina is available in satellites and rod/cylinders. 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination. They have great wear rate generally better than 90% or 99 ...

Read More

Overflow VS Grate Discharge Ball or Mill - Why Retrofit - 911

2015.6.24 Grate Discharge Ball Mills have shown 25% to 45% more tonnage ground and a substantial reduction in power consumed per ton of material compared size for size with overflow mills. To illustrate the characteristics of various type mills we have shown the types of discharge for rod mills and ball mills. There are essentially four types of rod mill ...

Read More

Wear ofgrinding media in the mineral processing

2018.11.9 These include semiautogenous (SAG) .mills, rod mills, conventional ball mills, and tower mills. The different types ofgrinding media available for these grinding applications include heat-treated and as-rolled grinding rods, forged steel balls, cast steel balls, cast high chrome iron balls, and cast slugs (or cypebs). Some media types are best ...

Read More

Ball milling: a green technology for the preparation and ...

The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the prep-

Read More

sbm/sbm ball mill diagram vibrator.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Read More

>> Next:Craigslist Broyeur à Marteaux