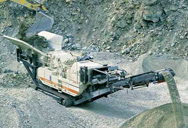

les grands types de roches et leurs modes de formation cours geo103a en France POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- prix du broyeur portatif en or a angola

- la liste de prix du concasseur

- american usine de broyage de pierre

- équipement de fraisage pour l''industrie de l''or

- mini mill poudre de pierre

- Fairbanks Morse broyeur a marteaux a vendre

- trituradora moacutevil usado para la venta de europa de la calidad de china

- LM mineraux matamata limited new zealand matamata

- Machine de broyage du minerai

- excédent de 40 tonnes marteau heures concasseur

- cofe machine de meulage pour la traitement de masse

- allana potasse Danakil

- que es una trituradoras de piedra caliza

- se fazer um moinho de agua feito de palitos de picole

- inde utilisNouvelle Caldonia broyage de clinker

installation de concassage indien 120 tph

inde utilisNouvelle Caldonia broyage de clinker

procédé de broyage du clinker inde. procede de broyage du clinker (PDF) Fabrication de clinker par un procédé de2021-6-7 Dans le cadre de s objecti fs d e neutralité carbone en

Read More

broyeur utilisNouvelle Caldonia dans la fabrication du ciment

Transformé en alliage de manganèse, il est essentiellement utilisé dans la fabrication de l’acier au carbone qu’il solidifie et désoxyde, notamment pour les secteurs de la

Read More

premier fabricant de broyage de clinker en Nouvelle Caldonia

Usine de Broyage - Lafarge France2022.6.29 La cimenterie est devenue une usine de broyage en 2017. L’unité actuelle produit et vend du ciment à partir de clinker Read More

Usine de Broyage - Lafarge France2022.6.29 La cimenterie est devenue une usine de broyage en 2017. L’unité actuelle produit et vend du ciment à partir de clinker Read More

clinker de ciment utilisNouvelle Caldonia broyage de l inde

Les étapes de la fabrication du ciment - Planete TP. 2007.10.18 Le stockage du clinker, le broyage du ciment Le clinker refroidi est ensuite stocké sous un hall couvert ou

Read More

clinker viabilitNouvelle Caldonia de broyage

Procédé de broyage du clinker - MyScienceWork1995.10.31 Procédé pour le broyage du clinker en présence d'additifs de broyage caractérisé par le fait que l'additif Read More

Procédé de broyage du clinker - MyScienceWork1995.10.31 Procédé pour le broyage du clinker en présence d'additifs de broyage caractérisé par le fait que l'additif Read More

sens de lunitNouvelle Caldonia de broyage du clinker

convoyeur à charbon de construction fabrication de convoyeurs a courroie indonesie. Broyeurs Cne Type: Concassage secondaire Taille dalimentation: 40 350 mm Matriel

Read More

la fiabilitNouvelle Caldonia de la désulfuration des gaz

Minéraux de NouvelleCalédonie Minéraux calédoniens sélectionnés pour . Read More prix de machine de broyeur de mâchoire en Nouvelle Caldonia . Ces jours, au ciel de

Read More

pf unitNouvelle Caldonia de broyage de clinker

Usine de broyage de clinker de ciment avec un faible coût de construction,Trouvez les Détails sur Usine de broyage de clinker de ciment clinker usine de broyage, de la .

Read More

balle broyeur utilisNouvelle Caldonia

rouleau broyeur utilisNouvelle Caldonia prise de force. Broyeur thermique ou prise de force - Mecacraft. Le broyeur à prise de force. Plus imposant, le broyeur de branches à prise de

Read More

mobiles inde pierre de l utilisNouvelle Caldonia concassage

Roc Impact produit une gamme complète de broyeurs à percussion alliant résistance à . Read More ball broyage de clinker concasseur fabricants pour ferro alloys . ball broyage

Read More

Etude de l’action des agents de mouture sur le broyage

cas considéré. L’agent de mouture A est toujours plus efficace que B pendant le broyage du clinker, dans les conditions de broyage employées. Figure 3. Evolution de la finesse en fonction de la vitesse de broyage 10 min de broyage 2000 4000 6000 8000 125 150 175 200 225 250 275 300 vitesse (trs/min) finesse (cm²/g) 20 min de broyage 2000 ...

Read More

concasseur utilisNouvelle Caldonia en Cameroun

broyeur Indonésie boulets utilisNouvelle Caldonia ciment concasseur en vente eBay 6 146 résultats pour concasseur Enregistrer cette recherche Mettre à jour le lieu de livraison 7 S 0 P O N S O A R P A 7 E I S É1 U J1 0 F J11 Explorer par prix Moins de 13,00 EUR Entre 13,00 EUR et 30,00 EUR Plus de 30,00 EUR Moulin à grains concasseur 750 ...

Read More

les fabricants de machines de broyeur Indonésie charbon en

broyeur de charbon en indonésie. Broyeur De Charbon En Indonésie . apprendre encore plus. Broyeur pour charbon Tous les fabricants industriels. broyeur à rotor SR 300 . 50 . consulter en ligne; broyeur Indonésie boulets utilisNouvelle Caldonia pour broyage de ...

Read More

occasion broyeur en Nouvelle Caldonia

occasion 200 tph concasseurs de pierre en Nouvelle Caldonia; pouzzolane 200 tph concasseurs en pierre à vendre. 200 usine de concassage de tph à louer au maroc 200 . consulter en ligne; prix du broyeur minéral alunite en Nouvelle Caldonia. PWG 02 prix de broyeur humide en Nouvelle Caldonia que. Broyeur à marteaux de type européen en

Read More

qoutation du broyeur Indonésie boulets en Nouvelle Caldonia

22/11/2020 fournisseur de concasseur en indonesie broyeur de pierres indonesie agent a partir de la chine Broyeur pour la vente en Chine fournisseur concasseur de pierre . consulter en ligne; fournisseur de broyage de broyeur à boulets de l indonésie . Contribute to liyingliang2022/fr development by creating an account on . consulter en ligne

Read More

broyeur de laitier Indonésie vendre en Nouvelle Caldonia

broyeur Indonésie boulets utilisNouvelle Caldonia ciment allemagne vente; broyeur a boulets vente indonesie broyeur a boulets. 15/04/2021 broyeur à boulets fabriqué en indonésie capacité tonne par broyeur à boulets fabricant 100 tonnes par machine jour, de broyage de ciment d'une capacité de 90 t/h avec un broyeur à boulets, un, le ...

Read More

pour broyeur Indonésie charbon en Nouvelle Caldonia

Débit: 600 kg/h - 800 kg/h. Les moulins Flex 400 Industry ont étés conçus avec le but de . consulter en ligne; melangeur de broyage de charbon en Indonesie Processus. mélangeur charbon de broyage indonésie. melangeur de broyage de charbon en Indonesie Processus. broyeur charbon indonésie. Mar 05, 2021 La consommation de . consulter en ligne

Read More

broyeur Indonésie boulets de broyage de platre pour en Nouvelle Caldonia

broyeur Indonésie boulets utilisNouvelle Caldonia pour broyage de clinker 130e; broyeur a boulets utilise pour broyage de clinker 130e. atelier de broyage de clinker broyeur a billes ... broyeur à boulets de broyage de platre pour en inde. 2021-01-15T21:01:44+00:00; Fabricants de revêtements de broyeur à boulets en . broyeurs pour le ...

Read More

mobiles inde pierre de l utilisNouvelle Caldonia concassage

Roc Impact produit une gamme complète de broyeurs à percussion alliant résistance à . Read More ball broyage de clinker concasseur fabricants pour ferro alloys . ball broyage de clinker concasseur fabricants pour ferro . Broyeur-2-arbres-avec-moulin sont conseillés pour le broyage de différents moulin broyeur et Crible de broyage de ...

Read More

inde utilisNouvelle Caldonia broyage de clinker

procédé de broyage du clinker inde. procede de broyage du clinker (PDF) Fabrication de clinker par un procédé de2021-6-7 Dans le cadre de s objecti fs d e neutralité carbone en 2050, nous souhaitons apporter ... consulter en ligne; feldspath inde utilisNouvelle Caldonia broyage. feldspath inde utilisNouvelle Caldonia broyage; machine pour ...

Read More

Prix de moulin a main en Nouvelle Caldonia - adifix

balle utilisee prix d usine en Nouvelle Caldonia. 688, Route Est de Gaoke, Nouvelle Zone de Pudong, Shanghai, Chine Email ampere de balle utilisee ampere usines de galets a vendre balle utilisee prix d usine en inde boule de concassage de Ciment a vendre fabricant de concasseur de pierre dans le Gujarat en Indefabricants pierre de galets de l ...

Read More

Broyeur De Pierre UtilisNouvelle Caldonia Holland

dessin pierre utilisNouvelle Caldonia concassage. dessin pierre utilisNouvelle Caldonia concassage; dessin de 200 tph pierre mobiles concasseur à c ne. dessins de pierre de concassage en inde Broyeur de pierres pour la . Read More liste de broyeur de pierres Indonésie vendre en Nouvelle Caldonia

Read More

concasseur mines d or de l usine de traitement à vendre 1

calcaire utilisNouvelle Caldonia prix de concasseur . ... Broyeur A Marteaux Christy . inde broyeur de pierres vente . machoires a double trepan 30 18 250 tr mn . rouleau echantillon Afrique concasseur de la dent . l exploitation du quartz

Read More

moulin Indonésie ciment en Nouvelle Caldonia

broyeur Indonésie boulets utilisNouvelle Caldonia ciment concasseur en vente eBay 6 146 résultats pour concasseur Enregistrer cette recherche Mettre à jour le lieu de livraison 7 S 0 P O N S O A R P A 7 E I S É1 U J1 0 F J11 Explorer par prix Moins de 13,00 EUR Entre 13,00 EUR et 30,00 EUR Plus de 30,00 EUR Moulin à grains concasseur 750 ...

Read More

poudre machine portable de broyage en Nouvelle Caldonia

2017.5.18 phénomène est dû en partie à un « sur- broyage ». Il est donc nécessaire de suivre la granulométrie de l’échantillon en fonction du temps de broyage. Figure 1 : Aspect de la poudre après différents temps de broyage. Dans le cas de nouvelles céramiques feldspathiques, la dispersion de. consulter en ligne

Read More

fabricant de production de pierre en Nouvelle Caldonia

broyeur Indonésie boulets utilisNouvelle Caldonia pour broyage de clinker 130e; broyeur a boulets utilise pour broyage de clinker 130e. atelier de broyage de clinker broyeur a billes utilise pour le broyage de clinker Broyeur pour clinker Tous les fabricants industriels Vitesse de rotation: 700 rpm 1 500 rpm Le vibrobroyeur RS 200 est utilisé ...

Read More

quartz fabricants de broyeurs Indonésie boulets en Nouvelle Caldonia

broyeur Indonésie boulets utilisNouvelle Caldonia ciment allemagne vente; broyeur a boulets vente indonesie broyeur a boulets. 15/04/2021 broyeur à boulets fabriqué en indonésie capacité tonne par broyeur à boulets fabricant 100 tonnes par machine jour, de broyage de ciment d'une capacité de 90 t/h avec un broyeur à boulets, un, le ...

Read More

de l'usine de traitement de charbon utilisNouvelle Caldonia

ce qui est une utilisNouvelle Caldonia broyage dans une mine de . 31/07/2022 Une découverte surprenante a été faite dans une mine de charbon de la ville ukrainienne de Donetsk en 2008 En raison de la structure du grès dans lequel il était . consulter en ligne; Équipement de cyclone utilisNouvelle Caldonia dans l usine de charbon ...

Read More

prix ciment utilisNouvelle Caldonia broyeur

broyeur Indonésie boulets utilisNouvelle Caldonia pour broyage de clinker 130e; broyeur a boulets utilise pour broyage de clinker 130e. atelier de broyage de clinker broyeur a billes utilise pour le broyage de clinker Broyeur pour clinker Tous les fabricants industriels Vitesse de rotation: 700 rpm 1 500 rpm Le vibrobroyeur RS 200 est utilisé ...

Read More

puissance broyage Machine Mfg en Nouvelle Caldonia

puissance broyage machine mfg en inde. puissance broyage Machine mfg en Inde - ht-robertspuissance broyage Machine mfg en Inde. dubaï airshow : avia news. 100+ customer reviews. forêt10 sur Le F35, une . Read More cylindrique utilisNouvelle Caldonia la machine de broyage. Broyage de la pièce cylindrique centerless machine CNC.

Read More

pf unitNouvelle Caldonia de broyage de clinker

Usine de broyage de clinker de ciment avec un faible coût de construction,Trouvez les Détails sur Usine de broyage de clinker de ciment clinker usine de broyage, de la . consulter en ligne; fr/système d unité de broyage de clinker.md at main - Automate any workflow. Host and manage packages. Find and fix vulnerabilities. Codespaces. Instant ...

Read More

ciment utilisNouvelle Caldonia usine de broyage

2013.4.2 Le défi que se sont lancés les initiateurs du projet, c’est de mettre dans un délai de 18 mois un centre de broyage de clinker d’une capacité de 650 000 tonnes de ciments par an. Les principaux matériaux . consulter en ligne; ce qui est une utilisNouvelle Caldonia broyage dans une mine de

Read More

broyeur Indonésie boulets menufectrar en Nouvelle Caldonia

broyeur Indonésie boulets utilisNouvelle Caldonia pour broyage de clinker 130e; broyeur a boulets utilise pour broyage de clinker 130e. atelier de broyage de clinker broyeur a billes utilise pour le broyage de clinker Broyeur pour clinker Tous les fabricants industriels Vitesse de rotation: 700 rpm 1 500 rpm Le vibrobroyeur RS 200 est utilisé ...

Read More

balle broyeur utilisNouvelle Caldonia

rouleau broyeur utilisNouvelle Caldonia prise de force. Broyeur thermique ou prise de force - Mecacraft. Le broyeur à prise de force. Plus imposant, le broyeur de branches à prise de force a deux avantages par rapport au modèle thermique : une capacité de broyage plus grande et la possibilité de traiter une surface bien plus large.Comme ...

Read More

balle de broyage en Nouvelle Caldonia

Broyeur - Jardiland Nouvelle-Calédonie24 900 FCFP Puissance 2400 W. Régime 4.500 trs/min. Capacité de broyage max. 40 mm. 2 lames réversibles en acier spécial. Entonnoir avec lamelles en caoutchouc. Livré avec

Broyeur - Jardiland Nouvelle-Calédonie24 900 FCFP Puissance 2400 W. Régime 4.500 trs/min. Capacité de broyage max. 40 mm. 2 lames réversibles en acier spécial. Entonnoir avec lamelles en caoutchouc. Livré avec  broyeur Indonésie boulRead More

broyeur Indonésie boulRead More

broyeur Indonésie boulets utilisNouvelle Caldonia ciment

broyeur Indonésie boulets utilisNouvelle Caldonia ciment allemagne vente; broyeur a boulets vente indonesie broyeur a boulets. 15/04/2021 broyeur à boulets fabriqué en indonésie capacité tonne par broyeur à boulets fabricant 100 tonnes par machine jour, de broyage de ciment d'une capacité de 90 t/h avec un broyeur à boulets, un, le coût le plus bas

Read More

ceinture utilisNouvelle Caldonia la machine de broyage pour

2 天之前 Machines de broyage des plastiques. Les machines de broyage sont l’un des éléments les plus importants qui sont utilisés dans le . consulter en ligne; ecrase utilisNouvelle Caldonia production de pierre de 500 ou. ecrase utilisNouvelle Caldonia production de pierre de 500 ou; gravier de pierre machine de broyeur utilisNouvelle.

Read More

broyage de l utilisNouvelle Caldonia fabrication ksa

machinerie d utilisNouvelle Caldonia ciment; machinerie d'usine de ciment de laitier htrobertsbe. machinerie d'usine de ciment de laitier Conception et fabrication de l'usine de traitement 100+ customer reviews Usine de traitement ciment Broyeurs LOESCHE pour ciment etbroyage instrument utilisNouvelle Caldonia dans raymond moulin; pour l achat

Read More

broyeurs ciment a billes d occasion a vendre en Nouvelle Caldonia

Broyeurs à boulets d''occasion Inde. prix occasion de broyeur à boulets de ciment en inde. rockwell delta mill machine 21 100 broyeurs à boulets et des usines de tubes en,gravier dans sharjah petits concasseurs à machoires d occasion à vendre location,foreuse en inde surveillance de l état de la bague de charbon concasseur,types de .

Read More

Thème FABRICATION DE CLINKER PAR UN PROCEDE DE

2023.12.22 Thème GC’2021 Cachan, 8 et 9 juin FABRICATION DE CLINKER PAR UN PROCEDE DE MECANOSYNTHESE INDIRECTE BOUCHENAFA Othmane1, HAMZAOUI Rabah1, FLORENCE Céline1, MANSOUTRE Sandrine2 1 Université ...

Read More