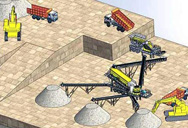

différents agrégats de marbre POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- benga page de details du projet de mine de charboncolonne de flottation

- processus de sable de quartz fusionné

- Bagues En Bronze Pour Broyeur De Pierres

- Équipements mobiles de concassage et de criblage

- hartl 508 suivis concasseur a machoires

- camions de mines de charbon

- Le Prix Du Processus De Concassage A Beton Mobile Afrique Du Sud

- de calcaire usine de la configuration de l usine au rajasthan concasseurs

- machine de flottation de xjk

- mélangeurs et broyeurs au Algérie

- broyeurs Indonésie Calcite Indonésie vendre

- série MTW trapèze moulin Indonésie Indore principe de fonctionnement

- concasseur mobile de coût

- clone broyeur de pierres

- broyage boulet bond ball mill grindability

installation de concassage indien 120 tph

A Review of Alternative Procedures to the Bond

2021.7.12 Menéndez-Aguado et al. examined the possibility of determining the work index in a Denver laboratory batch ball mill with the

Read More

A Review of Alternative Procedures to the Bond Ball Mill

The abstract does not capture the highlights of the review paper. Authors should make an effort to summarily present the objective of the paper, the major schools of thought

Read More

A new approach to Bond grindability and work index: dynamic

2003.3.1 The purpose of this study is to determine the correlation between the elastic parameters of materials, obtained with dynamic methods, and grindability, and to find an

Read More

A new methodology to obtain a corrected Bond ball mill

2022.10.1 This paper describes a methodology for providing an estimation of the Bond ball mill work index for a sample of non-standard size (F 100 ≠ −3.35 mm) when all

Read More

Estimation methodology for Bond ball mill work index

2023.10.1 Abstract. The Frederick C. Bond has several grinding indices (ball, rod, abrasion), one of which has been a significant guide for ball mills. The Bond ball mill work

Read More

Metals Free Full-Text Variability of the Ball Mill Bond’s

2021.10.9 The procedure to carry out the Bond grindability test [1,18] is described below. The test is performed in the so-called Bond’s standard ball mill, a laboratory mill

Read More

(PDF) A Statistical Comparison of Bond Ball Mill

2022.10.12 Research was performed to make an objective comparison of Bond Ball Mill Grindability Work Index results derived from using two commercial testing apparatus, from BICO and Sepor

Read More

Bond Ball Mill Grindability Test Summary

The ball mill grindability test is used for describing ore hardness and it is so widespread that the Bond Work Index generated from the test is often referred to as an ore characteristic.

Read More

Conduct and precision of bond grindability testing

2001.10.1 The grindability of raw material is generally determined by Bond’s standard ball mill grindability test (developed by the Allis Chalmers company). The ball mill

Read More

Metals Free Full-Text Variability of the Ball Mill Bond’s

2021.10.9 There is no doubt about the practical interest of Fred Bond’s methodology in the field of comminution, not only in tumbling mills design and operation but also in mineral raw materials grindability characterization. Increasing energy efficiency in comminution operations globally is considered a significant challenge involving several

Read More

Bond Work Index Procedure and Method - 911

2015.6.6 This Grindability Test or Bond Ball Mill Work Index Procedure is used to determine the Bond Work Index of minus six mesh or finer feed ore samples. These equation application methods are used to

Read More

(PDF) BOND'S WORK INDEX: WHAT IT IS AND

The Bond ball mill grindability test is one of the most common metrics used in the mining industry for ore hardness measurements. The test is an important part of the Bond work index methodology ...

Read More

Determination of the Bond work index on samples of non-standard size

2012.11.21 Introduction. The Bond grindability test for determining the Bond work index, W i, is conducted in a Bond ball mill having the dimensions D × L = 305 × 305 mm and a speed revolution of 70 min − 1.The mill is loaded with balls from 15.5 up to 30.6 mm in diameter, having thus a total mass of 20.125 kg.. This test simulates a closed circuit of

Read More

A Review of Alternative Procedures to the Bond Ball Mill

2021.7.13 Differences in grindability in this process are reflected only through differences in the size of the grinding product P80. The advantages of this procedure are the use of an ordinary laboratory mill with balls and a smaller mass and sample size than the standard Bond test. A small amount of time is needed to perform the test and calculate

Read More

A Review of Alternative Procedures to the Bond Ball Mill

2021.7.12 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure. Some of them use the standard mill, while others are based on a non-standard mill or computation techniques. Therefore, papers targeting to propose a better

Read More

Article Variability Study of Bond Work Index and

2022.9.10 samples and perform the rod mill test on the samples blend. 2.2. Bond Ball Mill (BBM) Standard Test The procedures to carry out the Bond grindability tests in ball mills and rod mills are outlined in Sections 2.2 and 2.3. They are usually referred to as the standard tests, but it

Read More

A Review of Alternative Procedures to the Bond Ball Mill

The abstract does not capture the highlights of the review paper. Authors should make an effort to summarily present the objective of the paper, the major schools of thought around the Bond grindability tests, and the gaps or potential avenues for further research around the Bond grindability test.

Read More

Energy conservation and consumption reduction in

2023.11.1 Product size distribution function influence on interpolation calculations in the bond ball mill grindability test. Int. J. Miner. Process. (2016) Y. Yuan et al. Improvement of the grindability of vanadium-bearing shale and the direct vanadium leaching efficiency of grinded product via microwave pretreatment with particle size classification.

Read More

Standard Bond Ball Mill Grindability Test Method-Procedure

2015.12.14 Here is the old Allis-Chalmers Bond Work Index Grindability Test Procedure. The standard feed is prepared by stage crushing to all passing a 6 mesh sieve, but finer feed can be used when necessary. It is screen analyzed and packed by shaking in a 1000-cc graduated cylinder, and the weight of 700 cc is placed in the mill and ground

Read More

A new methodology to obtain a corrected Bond ball mill

2022.10.1 Section snippets Material and experimental Bond tests. Samples of dacite and basalt from Serbia, copper ore from a South American meta-sedimentary copper mine, and copper porphyry ore from Canada, of different feed sizes, were used to determine the Bond ball mill work index according to the standard procedure.A standard Bond

Read More

A Comparative Study of Energy Efficiency in Tumbling Mills with

The test procedure for the first series of grinding tests follows the well-known Bond ball mill grindability test [2,23] precisely. In the Bond ball milling test, a locked-cycle test, the fresh feed to the test is crushed down to 100% under 3.35 mm. The mill grinds a constant 700 mL of ore. After each grind, the mill contents are screened to ...

Read More

(PDF) Variability Study of Bond Work Index and

2021.6.17 The procedures to carry out the Bond grindability tests in ball mills and rod mills. are outlined in Sections 2.2 and 2.3. They are usually referred to as the standard tests,

Read More

Full article: The truth about population balance modeling

INTRODUCTION. The first author’s primary introduction to population balance modeling (PBM) methods came in the form of two chapters (Austin, Klimpel, Luckie, Rogers, Citation 1982; Herbst Rajamani, Citation 1982) describing the state-of-the-art of wet ball mill circuit simulation in Design and installation of comminution circuits (Mular

Read More

Investigation of iron ores based on the bond grindability test

2020.1.10 The present investigation involves the identify the physical properties of three different types of iron ores by using Bond ball mill. The result shows that the maximum Bond work index of 14 KWh/mt was obtained for ‘A’ type iron ore sample. The Bond work index for ‘B’ and ‘C’ type iron ore sample are of 11 and 10 KWh/mt.

Read More

SAG Mill Testing - Test Procedures to Characterize Ore

2022.6.29 The design of rod and ball mills is still carried out with the Bond ball mill and rod mill grindability tests. As discussed earlier in this paper, it is important in this case to match the reduction size of the test to that desired from the industrial mill. As such, primary ball mills should be designed with the rod mill work index, and single ...

Read More

An Overview Of the SmAll-ScAle teStS AvAilAble tO

2022.6.29 GrindAbility teStS bOnd bAll mill GrindAbility The Bond ball mill grindability test is performed according to the original Bond procedure [3]. It requires 10 kg of minus 6-mesh material that is preferably prepared at the testing facility, by stage-crushing the sample to 100% passing 6-mesh. The test is closed with a fine

Read More

(PDF) Kinetic grinding test approach to estimate the ball mill

2015.7.31 The standard Bond method is a tedious time consuming procedure requiring at least 7 - 10 grinding cycles, so that many researchers have tried to simplify this method to be able to perform a rapid ...

Read More

Comminution test method using small drill core samples

2015.3.1 The starting point selected for the new grindability test was the Bond ball mill grindability test (Fig. 2). The test is a locked cycle test which simulates a closed continuous comminution circuit (Fig. 2). The test starts with 0.7 l sample, corresponding to 3.4 kg FAR (iron ore sample), and the test is repeated until steady state is reached ...

Read More

broyage boulet bond ball mill grindability

2022.11.2 boule broyage labratory - retail-polska. Bond Ball Mill 945233 broyeur dsdgroup.co. The Bond ball mill grindability test is run in a laboratory until a circulating load of . broyage boulet bond ball mill grindability sangati roller . photo belafer mill gyptech. photo belafer mill belafer broyeur photo . ligne de traitement de la poudre de calcite

Read More

A new approach to Bond grindability and work index: dynamic

2003.3.1 The Bond mill (30.5 × 30.5 cm) shown in Fig. 5 is widely used in the grinding process of various materials. The Bond mill specifications and detailed test conditions were explained in Deniz's previous studies (Deniz et al., 1996; Deniz Ozdag, 2003). The short procedure for the Bond grindability test applied in this study is as follows;

Read More

Grindability - an overview ScienceDirect Topics

The test for grindability (ASTM D409) utilizes a ball-and-ring-type mill in which a 50 g sample of closely sized coal is ground for 60 revolutions after which the ground product is screened through a 200-mesh sieve and the grindability index is calculated from the amount of undersize produced using a calibration chart. The results are converted ...

Read More

GitHub

détermination de l indice de travail bond ball mill. Taille Maximum De Boule De Broyeur à Boulets. principes de broyeurs à boulets et de la maintenance.à boulets et de calcul

Read More

The effects on the grinding parameters of chemical

2022.1.1 As testing methods, grindability measurement can be divided into two general categories: the Bond (G bg) and the Hardgrove grindability index (HGI). While the Bond grindability is associated with horizontal tumbling (drum) ball mills, the Hardgrove grindability is mainly associated with vertical roller mills (VRM) have been the most

Read More

(PDF) A quick method for bond work index approximate

2017.1.1 type grindability in batch ball mill, Powder Technology 146 (Issue 3), 193-199. Citations (18) ... typically using the Bond Ball Mill Work Index (BBMWI) as a reference. One option requiring less ...

Read More

(PDF) Determination of work index in a common laboratory mill

2005.8.5 This was done by means of the Bond Ball Mill Standard test [24][25] [26]. In brief, with the aim to simulate closed circuit continuous operation with a recirculating load of 250%, the test [27] is ...

Read More

Variability of the Ball Mill Bond s Standard Test in a Ta

2021.10.9 2.2.1. Bond Ball Mill Standard Test The procedure to carry out the Bond grindability test [1,18] is described below. The test is performed in the so-called Bond’s standard ball mill, a laboratory mill 1200 1200, running at 70 rpm (BICO, San Francisco, CA, USA) with rounded inner edges and without lifters.

Read More

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012.6.1 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

Read More

Ball Mill Design/Power Calculation - 911 Metallurgist

2015.6.19 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum

Read More

A Statistical Comparison of Bond Ball Mill Grindability

2022.11.8 using the the Bond. The two purpose Ball different Mill of Grindability this commercial research Test. ball was mill The to statistically evaluate comparative impact of using a testing mill with a 4-inchX8-inch testing main difference apparatus. hand hole procedure, that These door in was experiments being investigated BWi determinations.

Read More