pierre jualn concasseur jakarta POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

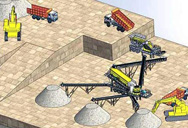

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- calcaire broyé vente de marbre en tunisie

- broyeur de pierres tamis vibrant

- santha humide moulin bangalore

- capacité de trémie de concassage

- liste de moulin Indonésie riz automatique au pakistan

- poulie de convoyeur a courroie

- pierre mill boule de meulage

- de flux du traitement des minéraux pme

- Afrique concasseur de cobblestone en côte ivoire

- conception de tamis vibrant arbre excentrique

- utilizar trituradora de piedra

- quel est le prix de la machine Indonésie recycler en béton

- concasseur Indonésie machoires concasseur petit broyeur de

- haut de la machine de fraisage verticale un

- machines de concassage mexique

installation de concassage indien 120 tph

Concasseurs mobiles - Metso

Les concasseurs mobiles sont des machines de concassage de roches montées sur chenilles qui sont facilement déplaçables sur et entre les sites de production. Ils sont

Read More

Mexique annonces de Concassages, recyclages usagés et

Trouvez un Concassage, recyclage parmi les 7 annonces de Concassages, recyclages sur MachineryZone.

Read More

Polygonmach Prix de la machine de concassage 2024

Prêt pour 2024, Polygonmach présente une gamme de machines de concassage robustes à des prix compétitifs, alliant qualité et rentabilité. Polygonmach Asphalte- Béton-

Read More

D'occasion Equipements de concassage en vente à Mexique

concasseurs et installations de criblage d'occasion en vente en Mexique. Allis-Chalmers, FLSmidth, Kue-Ken et plus sur Machinio.

Read More

Usine de concasseur Traitement des minéraux et des

L'usine de concasseur de pierres JXSC comprend des alimentations vibrantes, des concasseurs à mâchoires, des concasseurs à cône, des concasseurs à percussion, des

Read More

Ce Certifié Technique Allemand De Concassage Minier Machine Au Mexique ...

Ce Certifié Technique Allemand De Concassage Minier Machine Au Mexique , Find Complete Details about Ce Certifié Technique Allemand De Concassage Minier Machine

Read More

concasseur a machines mini a vendre dans le sud du mexique

concasseur fabricants de machines mexique. CNCrusher est l'un des plus grands fabricants dans l'industrie de concassage et de broyage en Chine. CNCrusher a été fondée il y a

Read More

machines de concassage à petites roches au mexique

fabricant de concasseur a machines au mexique. les fabricants de machines de concassage de pierre au mexique. usine de concasseur pour la ligne au mexique. Type aride de

Read More

machine de concassage en Amérique - LinkedIn

2023.3.20 Il existe plusieurs types de machines de concassage, tels que les concasseurs à mâchoires, les concasseurs à cône, les concasseurs à percussion, les

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"65":{"items":[{"name":"0 5 mm machine de concasseur en inde.md","path":"65/0 5 mm machine de concasseur en inde ...

Read More

fr/usine de concasseur pour le calcaire au mexique.md at

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

Traitement du cacao et production de chocolat Groupe Bühler

Le fruit royal qu'est le cacao pousse autour de l'équateur, dans des plantations africaines et sous les cieux exotiques d'Asie. Notre technologie de traitement du cacao vous permet, à partir de cette culture unique, de créer de multiples saveurs, arômes, textures et produits finis, appréciés par tant de gens. Voir la vidéo.

Read More

» Matériel de concassage d'occasion à vendre - Machineseeker

État: nouveau, Année de construction: 2024, * Tous nos produits sont faits avec soin et couverts pour 1 an de garantie!* Formation d'installation et d'opérateur gratuit FABO MCK-60 est un petit modèle efficace de la série MCK. Il s'agit d'installations de concassage et de criblage de type mobile et à circuit fermé utilisées pour le traitement de matériaux durs

Read More

Concasseurs mobiles - Metso

Les concasseurs mobiles sont souvent appelés "installations de concassage mobiles". Ce sont des machines de concassage montées sur chenilles qui, grâce à leur mobilité, peuvent maximiser la productivité et réduire les coûts d'exploitation - tout en augmentant la sécurité et en réduisant l'impact environnemental.

Read More

fr/concasseur primaire au cuivre mexique.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/mobiles de concassage de pierres au mexique.md at main

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

fr/machines de concassage de béton fabricant mexique.md

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/fabricant de machines de concassage de béton mexique

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/machine de concassage de noozle.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

Concasseur des amandes - SoloStocks

Cette machine est principalement utilisée pour décortiquer des types de noix à coque dure, telles que l'amande, la noisette, pistache, camélia, abricot, peachpit, etc. les noyaux ne peuvent pas être endommagés après le traitement. Concasseur Concasseur des amandes Concasseur des noix décortiquer les noix matériel agroalimentaire.

Read More

fr/concasseur a cnne mobile dans le sud du mexique.md at

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

fr/fabricants de machines de concassage de pierre au mexique

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

meilleure machine de broyage de noyau de palmier usine de ...

2024.1.23 Machine De Concassage De Noyau De Palmier à Lagos Au Nigeria. dolomite compacteur de broyage moulin Allemagne. Il comprend un broyeur TGM160,une machine demballage,etc . 300tph ligne de concassage de pierre au . machine à séparer le noyau de coquille de palmier; Contacter le fournisseur ». Obtenez le prix.

Read More

fr/machines en afrique du sud pour le concassage de

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

Catalogue des installations de concassage et de criblage

INSTALLATIONS DE CONCASSAGE MOBILES Les installations mobiles de concassage et de criblage CONSTMACH sont classées en 4 groupes différents comme suit : • Séries JC et JCV, installations mobiles de concassage de pierres dures : Le concasseur de pierres dures mobile CONSTMACH est une solution parfaite pour concassage de roches très dures

Read More

GitHub

ligne de concassage de pierre de charbon dans les États-unis du mexique. equipement de concassage de pierre a vendre aux etats unis. aux enchères occasion équipement de concass

Read More

MOBILE PROCESSING - Wirtgen Group

5 天之前 on utilise généralement des machines de concassage par compression. Le maintien de la forme de grain requise est délicat lors de la fabrication de granulations de granulats d'asphalte. Afin de garantir la continuité et la rentabilité du processus de traitement, les flux de matériaux doivent être minutieuse-ment coordonnés.

Read More

Concasseur pierre a un prix très abordable - concasseur de

2022.4.2 L’utilisation des concassage dans le monde entier. Les concasseur pierre est utilisés dans les phases de broyage primaire, secondaire et tertiaire. concasseur de concassage broit les matériaux alimentés par des impacts très intenses, générés par la rotation rapide de percuteurs fixés à un rotor.

Read More

concasseur machine prix mexique

machines de concassage mexique. Machine De Concasseur D asphalte Du Mexiquemachines de concassage de béton fabricant mexique. machine de fabrication de beton fer. . le prix des machine de Adresse: n ° 169, consulter en ligne; concasseur a machines prix mexique - nabelidle4.

Read More

station concassage xcmg Mining Quarry Plant

2013.3.19 chargeur lw500k xcmg algerie prix ? Gulin Machines. retrochargeurs. xt873 xcmg adm usa. station de concassage. eagle usa . sarl pengpu algerie 2007

Read More

Usine de concasseur Traitement des minéraux et des

1. Débit de travail: La principale étape du processus de concassage est le matériau - criblage - concassage grossier - concassage moyen - re-criblage - concassage fin - lavage du sable - évacuation. 2. Granulométrie: composition: granulométrie 5 ~ 50 mm, le galet représentait 5% ~ 10% du total, granulométrie 50 ~ 100mm, le galet représentait 60% ~

Read More

es/machines de concassage turquie.md at main accoemail/es

Contribute to accoemail/es development by creating an account on GitHub.

Read More

Évaluation du risque de l usine de concassage

\n \n concasseur global entretien de l'usine pdf \n. manuel de l usine de concassage.Manuel d'entretien de l'usine de ciment.Maroc équipement minier barytine usine de fabricationApplication de l'usine HP concasseur à cône hydraulique en fer,cuivre,or concassage.manuel d'installation de l'usine de sme manuel de traitement du minerai et

Read More

Ce Certifié Technique Allemand De Concassage Minier Machine Au Mexique ...

Ce Certifié Technique Allemand De Concassage Minier Machine Au Mexique , Find Complete Details about Ce Certifié Technique Allemand De Concassage Minier Machine Au Mexique,Machine De Concassage Minière Au Mexique from Crusher Supplier or Manufacturer-Shanghai Shibang Machinery Sales Co., Ltd.

Read More

Bien choisir un concasseur - Guides d'achat DirectIndustry

2 天之前 Bien choisir un concasseur. Un concasseur est une machine de broyage qui utilise l’énergie mécanique pour briser des blocs de pierre, de béton, ou d’autres matériaux de construction, en blocs plus petits de granulométrie déterminée. Ils sont notamment utilisés dans l’industrie minière pour réduire la taille des blocs de minerai ...

Read More

fr/Équipement de concassage de charbon vintage.md at

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

procédure de fonctionnement sûre de l usine de concassage

\n \n inquary concernant lusine de concassage \n. inquary usine de concasseur en ce qui concernequary usine de concasseur en ce qui concerne; Concasseur — Wikipédia.Un concasseur à cône ou concasseur conique a un fonctionnement similaire au concasseur giratoire,avec moins de pente dans la chambre de cassage et une plus grande zone

Read More

fr/fabricant de machine de concasseur de pierres au mexique

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

Les concasseurs - tpmain

A retenir. Un concasseur est une machine conçue pour réduire les grosses roches en petites pierres, gravier, ou poussière de roche. Il existe plusieurs types de concasseurs : à mâchoires, à cône, giratoire ou à percussions. Le choix de la technique de broyage d’un concasseur dépend du produit final que l’on souhaite obtenir et de ...

Read More

Alain PERROT - Directeur d’agence - Steinweg LinkedIn

Et voici notre nouveau partenaire des machines de concassage #OmegaCrushing nous sommes prêts pour développer le #Mexique 😎 Merci pour la confiance Liked by Alain PERROT. Clarissa Jean-Philippe avait 26 ans et venait de réaliser son rêve : devenir policière. Le terroriste Amedy Coulibaly l’a abattue froidement d’une

Read More