cuchara trituradora de vehículo autopropulsado POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

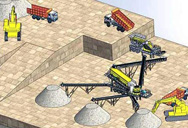

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- Meulage de pierre móvil de proyectos de construcción de carreteras

- Calcaire Broyage Du Ciment

- blindage pour des broyeurs Indonésie boulets

- broyeurs de ciment brique pour la maison au Pendjab

- les fabricants de bouteilles de verre millcrusher

- le meilleur ultrafines moulin de serie XZM montant

- séparateur de sable et fer Indonésie repasser pour la vente

- broyeur vertical à rouleau de Calcite en vrac

- mini fournisseurs de machines de fraisage

- machine à broyer le fournisseur

- mines et carrières dans Péroupedia

- trituradora de mandíbula placa móvil

- co251t de la machine usine de filtre Indonésie eau

- briques rouge capacite de production par tonnes

- equipments for quarrying jaw crusher

installation de concassage indien 120 tph

Jaw Crushers for Efficient Primary Size Reduction丨Sandrock

2024.1.11 Our jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries. With over-sized bearings

Read More

Jaw Crushers - Parker Plant

4 天之前 Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw

Read More

Mobile Crushers, Mobile Jaw Crushers Mobile Screens - SRP

Our high-capacity mobile scalpers are flexible and hard-wearing for virtually any application, including construction waste, landfill mining, quarry overburden, scalping before a

Read More

Mobile crushers and screens - SRP

We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone crushers, screens and scalpers

Read More

Jaw Crushers - Armstrong Equipment

Inside and out, the advanced engineering of our jaws sets industry standards with features like the pitman drop-forged 4340 chrome-moly-nickel steel shaft and spherical self

Read More

What Is A Jaw Crusher - MEKA

MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of

Read More

Selecting the right type of crushing equipment

2016.4.7 A ttrition crushers – which use both impact and grinding to shear material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle. Impact crushers utilise

Read More

Jaw Crushers - AGGRETEK Jaw Crushers for

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining Rock Quarries Sand and Gravel Construction

Read More

Terex Minerals Processing Systems JW SERIES JAW

2023.7.14 The jaw crushers handle ores, rock, gravel and recycled concrete. Each machine is backed by the Terex® Minerals Processing Systems total after-market

Read More

Mobile crushers and screens - SRP

This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects. Powerful, agile and fully mobile crushers ... Sandvik C12 jaw crusher. Feed

Read More

Crushing - Metso

Metso in-pit crush and convey (IPCC) solutions provide an integrated solution consisting of crushing, conveying, and stacking equipment combined with IPCC planning and life cycle services. Through the industry's strongest building blocks of team, technology and services, Metso is able to deliver successful IPCC operations.

Read More

What Are Jaw Crushers and How Do They Work?

2019.3.28 The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the

Read More

Used Heavy Machines Equipment For Sale in Saudi Arabia

SAR 550,000. (negotiable) Year: 2014. Serial: –. Condition: Used. Hours: –. For Sale. The Finlay® J-1175 tracked jaw crusher is a high performance and aggressive mobile crusher. The machine incorporates a heavy duty variable speed VGF and integrated prescreen to give optimum performance in quarrying, mining, demolition and recycling ...

Read More

Home - Maxwell Crushtech

Vast Industry Experience Since 1989, Professionals at Maxwell Crushtech made it one of the noted Exporter, manufacturer, Service Provider and Supplier of state-of-the-art Stone Crushers, Jaw Crusher, Cone Crusher, Grizzly Feeder, Vibrating Screen, Horizontal Shaft Impactor (HSI), Vertical Shaft Impactor (VSI), Sand Washing Unit, Crusher Plant, Sand

Read More

Crusher - Picson Construction Equipments

Crusher. Crushers are machines used to reduce the size of rocks, stones, and ore. They are often utilized in aggregates production, construction material recycling, and mining operations. PICS INTERNATIONAL offering covers different gyratory crushers, jaw crushers, cone crushers, and impact crushers – optimized for any size-reduction need.

Read More

Crushing Conveying - Mining Technology

Design and Manufacture of Jaw Crushers, Impact Crushers and Portable Crushing Plants. Loesche GmbH. ... Aftermarket Wear Parts and Crusher Spares for Quarrying and Mining. R. Rambooms. Customisable Breaker Booms for Mining Applications. RUD ERLAU. Mining Tyre Protection and Mining Tyre Chains. S.

Read More

Roljack Asia Limited - JAW CRUSHER

This design provides excellent fatigue strength even in toughest quarrying or mining application. Roljack Jaw Crusher are the most productive and cost-effective jaw crusher for any primary secondary crushing application. Jaw crusher were originally developed to crush the hardest ores and rocks so they perform extremely well also in less ...

Read More

Jaw Crusher - Heavy Duty Jaw Crusher Latest Price,

Roljack Asia Limited. Contact Supplier. Delhi Scientific Mild Steel Jaw Stone Crusher Manufacturer, Capacity: 300 KG To 500 Ton Per Hour. ₹ 50,000. Delhi Scientific. Contact Supplier. Mild Steel 48"x36" (1200x950mm) - Primary Jaw Crusher. ₹ 65 Lakh. Deepa Machinery Manufacturers Private Limited.

Read More

Evaluation of blast fragmentation effects on jaw crusher

2021.9.21 As a second step of the jaw crusher performance observations, crushing times of the jaw crusher were measured and recorded for each truckloads of blasted rock. In total, 82 truck-loads of particles were analyzed and the jaw crusher’s throughput considering these loads was measured and recorded. After obtaining 82 particle size distribution ...

Read More

crusher ne fluorite process production line in thailand

Fluorite is widely used in many industries In order to improve the production efficiency, we need to use the high quality fluorite quarrying equipment and reasonably design the fluorite processing linecone crusher economy in thailand cone crusher economy in thailand; Customer Case Stone Crushing Plant Stone crushing plant is also called rock ...

Read More

Jaw Crushers – MEKA

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other makes an eccentric movement. There are also primary

Read More

Jaw Crusher Manufacturers in Faridabad - Pultvizor

In quarrying operations for the primary crushing of quarry materials ... We are one of the leading Jaw Crusher Manufacturers in Faridabad producing crushers with robust construction and offer superior strength which ensures their durability and longevity. Our expert team of engineers and technicians has designed the crusher to withstand the ...

Read More

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

颚式研磨仪应用领域. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under rough conditions but are also suitable for on-line quality control of raw materials. The main fields of ...

Read More

Portable Crushing Plants Sepro Crushing and Screening

The impact crusher mounted on the portable chassis provides a host of benefits compared to cone crushers and jaw crushers. By being able to function as both a primary and secondary crusher, the Impactor 5000 can house both the impact crusher and screen on a single trailer—rather than two or three!

Read More

granite quarry stone crusher machine - LinkedIn

2023.7.7 Here are some common types of stone crusher machines used in granite quarrying: Jaw Crusher: Jaw crushers are commonly used as primary crushers in granite quarry operations.

Read More

What Is Jaw Crusher – Powerups Crusher

2022.9.20 A jaw crusher uses compressive force for breaking materials. This mechanical pressure is achieved by the two jaws die of the crusher, one of which is stationary and the other is movable. These two vertical manganese jaw dies to create a V-shape crushing chamber. The electrical motor drives transmission mechanism driven

Read More

Jaw Crusher Machine Manfucturers in India Picson

Jaw Crusher Manufacturer. jaw crushers reduce large-sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts a force on the feed material by pushing it against the stationary plate.

Read More

Site safety and safer aggregate crushing operations - Quarry

2020.4.17 It is important to make sure that crusher operators follow all operational guidelines and that all safety best practices are in place but also that the entire workforce is properly trained in site safety procedures and best practices. Regular safety meetings should be held to review new procedures or address any safety concerns.

Read More

CD Waste Recycling Plant - Picson Construction Equipments

PICS INTERNATIONAL Dry line system is the process of using recycled aggregate from construction and demolition waste in which CD waste collected to feed into the crusher for converting the big size demolition waste into suitable size of aggregate like 40mm, 20mm and 10mm. after that recycled aggregate is used in concrete in which further ...

Read More

Jaw Crusher (PE Series Primary Crusher) GTEK - GTEK

2023.5.15 Description. Jaw Crushers are mainly used as primary crushers in several applications including mining, quarrying, aggregates, recycling and construction industry. Jaw crushers are one of the most commonly used crushers due to their ability to crushes all kinds of materials of any hardness, as well as their low-cost operation and easy

Read More

Double Toggle Jaw Crusher Manufacturer in India Picson

While Jaw Crushers are mostly used as the first stage of material reduction in systems that may use several crushers to complete the circuit, the Jaw Crusher has also been used as a second-stage crushing unit. Depending on the application requirements, Jaw Crushers can be used in stationary, wheeled portable and track-mounted locations.

Read More

Jaw Crushers - Parker Plant

4 天之前 Jaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the up-thrust toggle RockSizer / StoneSizer model and down-thrust toggle RockSledger model.

Read More

What machines are used in quarry mining? What is the role

2023.2.7 ZENITH Mineral Crusher. In quarry mining, the following machines are commonly used: Excavators: Used for digging and removing earth and other materials from the quarry. Loaders: Used for loading ...

Read More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the ...

Read More

Aggregates Equipment John Deere US

Aggregates Equipment. Whether it's large excavators, big dump trucks or off road heavy equipment, John Deere's aggregate line up has it. From excavation to load and haul, crushing or screening, our machinery has the power, efficiency and the reliability you are looking for. Explore our mining and quarry line up to find your perfect combination ...

Read More

How much to open A Quarry? What Equipments are needed?

2019.8.12 What equipments are needed for a quarry. Quarry generally needs feeder, crushing equipment, screening equipment, transport equipment and so on. ... Jaw crusher has large output and high crushing ratio. Luoyang Dahua jaw crusher has solid structure, movable jaw assembly are durable and stable, jaw plate has high utilization that reduce

Read More

Types of Rock Crushers Quarry Crushing Equipment Kemper

6 天之前 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2.

Read More

Nordberg® C Series™ jaw crushers Proven reliability and

2021.7.16 Nordberg® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

Read More

Types of Crushers: What You Need to Know - Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Read More