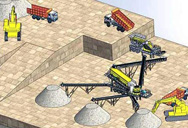

dc broyage automobile et de la machine de fraisage POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- de concasseur a cone broyeur a boulets

- équipements de concassage construction en afrique du sud

- Liste Des Fabricants De Concasseurs Indonésie Mâchoires

- pierre de savon unité de concassage

- fabricant tunnel de séchage de sable

- Conception De La Machine De Concassage Plastique

- ilmenite concasseur de minerai

- marque concasseur à machoires

- ampli busting operation de broyage

- usine de fabrication de sable en inde concasseur piste

- concasseur de pierre de construction rajasthan

- theorie du concasseur de machoires

- exigence de rouleau rectifieuse en inde

- concassage mobile grand

- rotary dryer for manganese ore

installation de concassage indien 120 tph

Preheating manganese ore in a pilot-scale rotary kiln

2021.2.1 PREMA : A H2020 European project. Energy efficient, primary production of manganese ferroalloys through the application of novel energy systems in the drying and pre-heating of furnace feed materials. PREMA objectives. Capture CO from the EAF

Read More

5 Easy but Efficient Steps to Realize Manganese Ore Processing

2023.4.10 The complete processing flow of manganese ore mainly includes five steps: crushing, washing, grinding, dressing, and drying. Next, I will introduce the

Read More

A sustainable reduction roasting technology to upgrade

2021.2.15 In this case, roasted manganese ore fines and manganese GCP sludge have been blended in a 1:4 ratio (165 tons + 48 tons) and briquetted using cement and

Read More

Industrial Mineral Rotary Drum Dryer for

2024.1.6 Industrial Mineral Rotary Drum Dryer for Manganese Iron Ore, Gypsum, Sand, Coal, Sludge, Slag, Slurry, Limestone, Ore Powder,

Read More

Rotary Dryer - JXSC Machinery - Mineral Processing

2 天之前 Overview Rotary dryer is also called long drum dryer or drum dryer. It is the most common kind of dryer equipment in mining equipment. It has high production efficiency,

Read More

Large Capacity Rotary Type Rotary Dryerfor Manganese Ore,

2023.7.18 Large Capacity Rotary Type Rotary Dryerfor Manganese Ore, Mixed Concentrate, Iron Ore, Find Details and Price about Rotary Drum Dryer Dryer Machine

Read More

Jiutian Manganese Ore Rotary Dryer Mineral Slag Drying

Jiutian Manganese Ore Rotary Dryer Mineral Slag Drying Machine , Find Complete Details about Jiutian Manganese Ore Rotary Dryer Mineral Slag Drying Machine,Mineral Slag

Read More

Performance evaluation of a flighted rotary dryer for lateritic ore

2023.11.1 The lateritic ore drying in the Cuban nickel producing industry is realized within flighted rotary dryers. In this investigation, performance indicators in regards to

Read More

Rotary dryer - HONGJI Machine

2023.11.30 Hongji's rotary dryer can dry more than 200 kinds of materials, including slime, limestone, river sand, clay, iron oxide scale, sludge, coke, copper concentrate, silicon carbide powder, rare earth ore,

Read More

Method to determine the decrepitation index of South African manganese ...

2022.1.1 Method details. The method was adopted from ISO 8371 (2004) [1] which is a method used to quantify the decrepitation index of iron ores in a muffle furnace at 700°C, as well as other source of literature on factors causing fines generation during a tumbling test (Kingman et al., 2008 [2]).The method was then adapted to suit the objectives of

Read More

Rotary Dryer - JXSC Machinery - Mineral Processing

2 天之前 JXSC rotary dryers use reasonable operating parameters; the coal consumption and electricity consumption are reduced by more than 10-15% compared with the general dryer, and the output when the machine is increased by more than 10-15%. ... Tin Ore Process Plant; Manganese Ore Process Plant; Lead Zinc Ore Processing; Contact Us

Read More

Rotary Dryer

2023.11.3 Rotary dryers work by tumbling material in a rotating drum in the presence of a drying air. They can also be indirectly heated to avoid direct contact between the material and processing medium. Applied material : Rotary dryers are essential dryers for mineral processing. Hongji's rotary dryer can dry more than 200 kinds of materials,

Read More

Manganese ore reduction calcination method and apparatus

2008.11.25 1. manganese ore reduction calcination method, it is characterized in that: the dioxide ore for manganese after will drying earlier is crushed to<granularity of 15mm, with reducing powder with 10: the 0.5-2 ratio, evenly stir, be delivered to stoving oven its top feed storehouse, enter in several airtight roasting devices, a plurality of ...

Read More

A sustainable reduction roasting technology to upgrade

2021.2.15 Reduction roasting of manganese ores is a known process; however, it is not yet commercialized mainly due to various techno-economic issues. The current research work presents results of a large-scale plant trial performed at a commercial Direct Reduced Iron making plant to upgrade low-grade ferruginous manganese ores (Mn: 25–32%,

Read More

Carbothermal Reduction of Manganese Oxide in Different

2008.10.16 C arbothermal reduction is the major industrial method for processing manganese ore and has been intensively studied.[1–12] At temperatures at which manganese ore is solid (usually below 1200 °C depending on the ore), manganese oxide is reduced quite slowly.That is why in the industrial production of manganese alloys in blast

Read More

Preheating manganese ore in a pilot-scale rotary kiln

2021.2.1 PREMA - Energy efficient, primary production of manganese ferroalloys through the application of novel energy systems in the drying and pre-heating of furnace feed materials This project has received funding from the European Union’s Horizon 2020 research and innovationprogramme under grant agreement No 820561 Vernon Rotary

Read More

What is ISO Certificated Rotary Drum Dryer for Sand/Coal

What is ISO Certificated Rotary Drum Dryer for Sand/Coal Slurry/Poultry Manure/Lithium Slags/Slime/Ore Powder/Black Iron-Manganese Ore Rotary Drum Dryer, Mineral slag dryer manufacturers suppliers on Video Channel of Made-in-China.

Read More

Efficient improvement for dissociation behavior and thermal ...

2020.7.1 Traditional smelting process of manganese ore was plagued with high consume of power and coke, and spraying and slag turning accidents caused by violent decomposition of carbonates and manganese oxides in manganese ore. In the present work, the thermal decomposition mechanism and phase structures of manganese ore were

Read More

Factory Directly Mineral Drying Machine Manufacturer

2023.7.13 Ore Dryer Working Principle Mineral raw materials are fed into the hopper through belt conveyor, and then enter the drying system through feeding mechanism. The guide device installed in the rotary dryer lifts the materials to the top and then drops them. When the material falls, it is broken by the high-speed rotating blade in the dryer.

Read More

Manganese Ore Processing Technology and

2019.7.2 The technological process of dealing with manganese oxide ore is generally crushing the ore to 6 ~ 0 mm or 10 ~ 0 mm, then classification, jigging at the coarse level and shaking at the fine level.

Read More

Method to determine the decrepitation index of

2022.5.1 Cracking of iron ore during thermal decomposition and reduction degradation is related to the volatilization of minerals containing volatile substances [6], thermal expansion and phase ...

Read More

11.5 Refractory Manufacturing - US EPA

2015.9.10 11.5.1 Process Description1-2. Refractories are materials that provide linings for high-temperature furnaces and other processing units. Refractories must be able to withstand physical wear, high temperatures (above 538°C [1000°F]), and corrosion by chemical agents. There are two general classifications of refractories, clay and nonclay.

Read More

Titanium Concentrate, Coal, Manganese Ore Drying Machine

2023.4.12 Titanium Concentrate, Coal, Manganese Ore Drying Machine, Find Details and Price about Gold Powder Dryer Wood Chips Dryer from Titanium Concentrate, Coal, Manganese Ore Drying Machine - Gongyi Hengchang Metallurgical Building Material Equipments Plant. Print This Page. Home Industrial Equipment Components Drying

Read More

Rotary Dryer Design Working Principle - 911 Metallurgist

2016.6.1 Rotary driers have thermal efficiencies of from 50 to 75 per cent on ores. This must be taken into account when using the above table, which is figured at 100 per cent. The drier shell is rotated separately from the stationary kiln section. To achieve the rotation a BULL GEAR is attached around the shell section.

Read More

AP-42, CH 11.30: Perlite Processing - US EPA

2015.9.10 Figure 11.30-1 is a flow diagram of crude ore processing. The first processing step is to reduce the diameter of the ore to approximately 1.6 centimeters (cm) (0.6 inch [in.]) in a primary jaw crusher. The crude ore is then passed through a rotary dryer, which reduces the moisture content from between 4 and 10 percent to less than 1 percent.

Read More

Pre-heating manganese ore in a pilot-scale rotary kiln

2021.2.12 In order to evaluate the potential of the rotary kiln, and to assess the feasibility and efficiency of this technology, Eramet Ideas conducted two continuous piloting campaigns with two manganese ore: Comilog, MMA grade, rich in high manganese oxides. Assmang, Nchwaning grade, rich in lower oxidized manganese phases but containing

Read More

PILOT PLANT STUDIES FOR THE PRODUCTION OF ELECTROLYTIC MANGANESE ...

1990.1.1 REDUCTION OF MANGANESE ORE NML has used both indirect-fired and direct-fired rotary kilns for reduction of ground manganese ore. ... NML installed an EMD pilot plant at Central Research Organization (CRO), Rangoon (Burma) in 1979. Manganese Ore ilndia) Limited will be commissioning a 700-tormes per annum EMD plant at Dongri

Read More

Mining Shaking Tables Gravity Separator - JXSC Machinery

1 天前 Introduction: In gravity separation, the shaking tables (gravimetric tables, shaker tables) are the most widely used and efficient sorting equipment for fine ore separation. The shaking table beneficiation is not just applied as an independent beneficiation method. Still, it is often combined with equipment such as jig separators, centrifugal concentrators, spiral

Read More

Rotary Dryers - FEECO International Inc.

2024.1.16 Rotary dryers are known as the workhorse of industrial dryers. They are able to process a wide variety of materials, and can lend a hand in nearly any industry requiring industrial drying solutions. Some of the most common industries and materials in which FEECO rotary dryers are employed include: Aggregates. Agricultural By-Products.

Read More

Pre-Drying of Chlorine–Organic-Contaminated

2022.12.10 In response to the current problem of the high energy consumption of direct thermal desorption systems when treating soils with a high moisture content, we propose using the waste heat of the system to

Read More

Manganese ore pre-reduction using a rotary kiln to

2019.2.28 D. Teguri, K. Saito, and Y. Miyauchi. Nippon Denko Co. Ltd, Tokushima Plant, Tokushima, Japan. Abstract – Nippon Denko Co. Ltd’s Tokushima plant produces low-phosphorus (≤ 0.050%), low-carbon (≤ 0.20%) ferromanganese (SLPFeMn) using a silicothermic process in a three-phase Heroult electric arc furnace. In the past, sintered

Read More

Using Polymetallic Nodules to Innovate Manganese Markets:

2023.1.6 Most historically view this residue as waste , but Randhawa, et al. , reported the laboratory scale production of a SiMn product from the residue containing 26% Mn, 10% Fe and 6% SiO 2 blended with manganese ore. The manganese recovery was 77%. Other manganese products proposed from hydrometallurgical flowsheets include MnCl 2 and

Read More

Filter Press - JXSC Machinery - Mineral Processing

2 天之前 The plate and frame filter press consists of chambers arranged alternately with filter plates and frames. The feed pump hydraulically pumps the suspension into the filter chamber, and the filter residue is formed on the filter cloth until the filter chamber is filled to form a filter cake. The filtrate passes through the filter cloth and flows ...

Read More

Mining Mineral Processing Equipment - FEECO

2023.6.16 FEECO offers a broad range of equipment and systems for agglomeration, granulation, drying, and high temperature thermal applications. Material can be tested on a single device, or as part of a continuous process loop integrating multiple pieces of equipment. Process experts can guide you through the testing process to provide the

Read More

Jig Concentrator Mineral Jig - JXSC Machine

2024.1.23 Jig Concentrator. 【 Capacity 】 1-20 T/H. 【 Material Size 】 2~18mm. 【 Type 】 Wet separation, dry separation. 【 Application 】 Jig concentrator is a gravity separator machine used to separate coarse grain ore in alluvial gold, crushed rock gold, coltan, tin, tungsten, diamond, barite, iron, manganese, fluorite, garnet, etc.

Read More

Study on the mechanism and kinetics of manganese release

2021.8.23 Manganese released from the piled manganese ore wastes is a great threat to the local ecosystem and human health. The mechanism and dynamic characteristics of manganese release from the manganese ore wastes were studied based on the static and dynamic experiments. The concentration of manganese in the leaching

Read More

Advances in dewatering and drying in mineral processing

2021.4.13 Abstract. In mineral processing, dewatering and drying are critical aspects from the technical and economical viewpoints. These operations should be considered carefully to achieve optimal water ...

Read More

The Maintenance and Use of Vibrating Screen - JXSC

2024.1.17 1. Check the anchor bolts. In the precautions for the use of vibrating screen, we need to carefully check the anchor bolts. This position is easy to loosen, once it is loose, it will produce great vibration and noise, even burn down the motor, which will cause great damage to the equipment. 2. Check the screen.

Read More

EXECUTIVE SUMMARY - DSIR

2020.3.18 EMD is generally produced from high-grade (50% Mn) manganese dioxide ore. Medium or low grade ore can also be used depending on impurities. Major countries exporting ore are South Africa other African countries, South America, Mexico and India. Generally, rotary kiln is used for the reduction of the ore using coke, coal, furnace oil or ...

Read More

>> Next:Procede De Calcul De Puissance De Broyage De Ciment