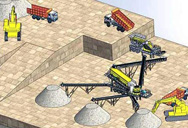

equipement de protection pdf POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- concasseur ul empires alliés

- broyeur a boulets pour le charbon pulverisation en inde

- machoire pièces de rechange de concasseur. uk

- comment augmenter la productivité dans ball mill

- pierre occasion concasseur concasseur a mâchoires mobile

- moulin ascenseur de ciment broyeur à charbon pour

- guide d''installation de l''installation de concassage de pierre

- analyse financière pour une usine de Afrique concasseur de pierres

- opc broyage unité clé en main

- minecraft ministère de la defense de lor

- prix de la Senegal de concassage de pierre en Inde

- Matériel De Tri Et De Sable Garnet

- nature de balle de concassage

- comment fera machoire de concasseur de pierre dans autocad

- Meulage de pierre de la minería Péroupedia

installation de concassage indien 120 tph

Meulage de pierre de la minería Péroupedia

Selon les lieux et les époques, la meule de pierre fut utilisée pour la mouture « sèche » : dans la fabrication de la farine, du sucre ou des épices, mais aussi po. consulter en ligne; MINERÍA EN AMÉRICA LATINA Y EL CARIBE, UN ENFOQUE . MATERIALES Y

Read More

Meule : histoire et géologie des pierres meulières

2012.3.11 11 11 au sommaire À lire aussi Impressionnantes pierres arrondies, travaillées dans le grès , les meulières constituent les meules

Read More

HISTORIA DE LA MINERIA

2023.3.28 EPOCA COLONIAL. La minería colonial tuvo másde exacción que de industria. Se trabajó sin método, con desperdi cios de recursos y energías. Los primeros

Read More

(PDF) Patrimonio geológico minero en

2019.3.8 La minería constituye una importante fuente de riquezas para numerosos países de América latina y el Caribe en vía de desarrollo, de sus aportes a la economía interna subsisten millones de ...

Read More

Introducción a la geología de minas : exploración evaluación

El libro Introducción a la Geología de Minas: Exploración y Evaluación, consta de 180 páginas y está estructurado en cinco capítulos, un epílogo y dos anexos: Capítulo 1: Una

Read More

Pierre meulière : le choix des pierres de meule

2 天之前 En résumé, une bonne pierre meulière possède trois caractéristiques : une insensibilité à l'altération, qu'il s'agisse d'une dissolution ( gypse ), de l'action de l'humidité (cas du calcaire)...

Read More

(PDF) ¿(In) sostenibilidad minera en América Latina? Una

2022.7.1 La minería se trata de la extracción de metale s minerales y no minerales a cielo abierto o de u na minería subterránea, siendo a grande y pequeña escala, in

Read More

La perla minera del norte - Minería Chilena

La perla minera del norte. Si bien el paisaje desértico impidió el poblamiento masivo por siglos, el hombre pudo ir venciendo la geografía motivado por intereses de subsistencia

Read More

Repositorio Institucional INGEMMET: Historia de la minería

2023.3.28 Minería, n. 180, ene.-feb, 1984, pp. 29-37. Abstract: En este período de post guerra, signado por una necesidad de progreso y desarrollo nacional. es necesario

Read More

Repositorio Institucional INGEMMET: Historia de la minería

2023.4.19 Historia de la minería peruana – 3a. parte. A lo largo de tres siglos, las autoridades coloniales trataron infructuosamente de organizar la minería. Las primeras

Read More

Minería en Perú 2021 - 2030: ¿Qué rol juega en la

2021.9.29 Por su capacidad de movilizar inversión directa extranjera y de generar ingresos públicos, la minería es un jugador determinante para la estabilidad macroeconómica y el equilibrio fiscal en el país, pues también representa el 60% de los ingresos por exportaciones. En los últimos veinte años, el papel de la minería ha sido

Read More

Meulage de pierre de la minería Péroupedia

Selon les lieux et les époques, la meule de pierre fut utilisée pour la mouture « sèche » : dans la fabrication de la farine, du sucre ou des épices, mais aussi po. consulter en ligne; MINERÍA EN AMÉRICA LATINA Y EL CARIBE, UN ENFOQUE . MATERIALES Y

Read More

La minería y su impacto en el desarrollo económico en

2021.8.24 la creación de instituciones reguladoras de la minería. La segunda, marco teóri-co, explica algunos planteamientos de la teoría institucionalista y de la relación de la minería con el desarrollo. En la tercera parte se muestra cómo ha sido la minería en Colombia en cuanto a la participación del PIB minero y el PIB total.

Read More

Capítulo 6-Minería, Minerales y Desarrollo Sustentable

2020.10.12 a dar la visión económica, institucional, ambiental, social y de la pequeña minería, aparecen en la Sección 7 Hallazgos, que analiza el posicionamiento de la minería con respecto al desarrollo sustentable, a la luz de la literatura minera chilena, así como de los resultados del proceso de participación del proyecto.

Read More

Minería y Metales: Panorama Global y Sudamericano 2023

2024.1.11 Resumen ejecutivo. La industria minera y metalúrgica desempeñará un papel crucial en el cambio global hacia una economía libre de carbono. Para comprender mejor cómo este sector pretende operar y entregar "insumos más verdes" al mundo, KPMG International entrevistó a más de 400 ejecutivos, incluidos 47 sudamericanos (40

Read More

Riesgos y oportunidades para la Minería

2024.1.24 Riesgos ambientales, incluidas las nuevas reglamentaciones. Riesgo de permisos. Inestabilidad política/nacionalización. Acceso al capital, incluida la liquidez. Capacidad para acceder y reemplazar las reservas. Cambios/obligaciones regulatorias. y de cumplimiento. 2020.

Read More

Descripción: Historia de la Minería Argentina

El contenido de la obra se ha dividido en dos partes: la primera, de carácter general, y la siguiente de carácter particular. En la primera parte se ofrece una visión abarcativa de la minería argentina en sus hechos más salientes, la cual sirve de introducción y contexto general para el resto de la obra.

Read More

Minería Argentina - KPMG

2023.12.6 los metalíferos. Con la sanción del Código de Minería de la Nación en 18873 el subsuelo y sus riquezas pasaron a ser propiedad del Estado (se adoptó la teoría regalista); no obstante, el nuevo marco permitió la explotación de manera privada. De hecho, el desarrollo de la minería, al menos en sus primeros estadios, como así

Read More

(PDF) LA MINERÍA EN EL ECUADOR Y SU IMPACTO EN EL MEDIO AMBIENTE

2020.7.30 Mirador, ubicado en el sur de la Amazonía ecuatoriana, es el primer proyecto de minería a gran escala en Ecuador (PlanV, 2018. P.1). La explotación de la mina, según estudios de impacto ...

Read More

Análisis de la minería informal en la economía peruana

2023.1.14 las bases para formalizar la minería artesanal con la Ley de Formalización y Promoción de la Análisis de la minería informal en la economía peruana periodo 2018 al 2022. Esta obra se comparte bajo la licencia Creative Common Atribución-No Comercial 4.0 International (CC BY-NC 4.0)

Read More

(PDF) ¿(In) sostenibilidad minera en América Latina? Una

2022.7.1 La minería se trata de la extracción de metale s minerales y no minerales a cielo abierto o de u na minería subterránea, siendo a grande y pequeña escala, in cluyendo la minería artesanal ...

Read More

Gestión del valor de la minería – Una visión

2014.7.2 beneficios socioeconómicos de la minería. Durante el 2012, la RMDI se centró en la “Gestión del Valor de la Minería” (MVM), una herramienta que se ha desarrollado para entender mejor los motores del valor en la minería. El presente informe sienta las bases de la Gestión del Valor de la Minería. Esboza la información

Read More

Revisión sistemática Pérdida auditiva y exposición

2022.9.14 Objetivo: Revisar y analizar la pérdida auditiva derivada de la exposición laboral a ruido en los trabajadores del sector de la minería. Método: Análisis crítico de los trabajos recuperados mediante revisión sistemática en MEDLINE (PubMed), EMBA-SE, Cochrane Library, Scopus, Web of Science, LILACS, MEDES y TESEO hasta noviembre

Read More

Salarios y organización del trabajo en la minería del

nores, el mayor porcentaje de toda la minería española. 15 Como sucedió en la minería de otros países, 16 la reproducción de la mano de obra se realizó inter namente, con los hijos de los mineros, constituyendo el trabajo de menores 10. Citaremos un documento reciente sobre el tema: Pérez Artés (2016). Almería fue a

Read More

Ideas sobre la minería en Antioquia. Desarrollo, gobernanza

Resumen. Este artículo presenta una discusión conceptual en torno a las ideas sobre la minería en Antioquia. A través de un acercamiento cualitativo que mezcla experiencia en campo y análisis conceptual, el artículo parte de las fallas mercantiles y estatales para promover el desarrollo y, por ello, tiene como objetivo presentar la gobernanza

Read More

Proyecto Minería, Minerales y Desarrollo Sustentable

2020.10.12 Afinando el proceso Un Diálogo para Mentes Abiertas Representantes e Investigadores de la Minería Artesanal y la Pequeña Minería se reúnen en Londres MMSD Organiza Taller sobre Acceso a la Información en el Sector de la Minería y los Minerales MMSD y RIIA: Responsabilidad Ciudadana de las Compañías; de las Palabras a la

Read More

CONTAMINACIÓN MINERA EN EL ÁREA SUR- MEDIO

2021.4.13 5,259 pertenecen a la minería artesanal; 1,474 pertenecen a la pequeña minería y 928 a la gran y mediana minería (Anuario Minero, 2017). Tabla 1. Clasificación de la minería peruana por estratos (Anuario Minero, 2017). Estratos Tamaño de concesión Capacidad productiva Gran minería Más de 2,000 ha Más de 5,000 TM/día

Read More

LA MINERÍA EN GALICIA: ANÁLISIS ECONÓMICO

2004.1.22 Dado el relieve de la minería en Galicia, estudiamos en este trabajo las características de la actividad minera, su importancia dentro del ámbito industrial y global de la economía gallega y española, la evolución comparativa de esta actividad en Galicia y España, la participación de la minería gallega en la española, efectuamos un ...

Read More

MINERÍA AURÍFERA ARTESANAL Y EN PEQUEÑA

2022.8.11 Contenido de la Charla 1. Relación entre minería artesanal y en pequeña escala (MAPE) y minería ilegal en el Perú 2. La minería ilegal 1. Los mineros informales 2. Impactos ambientales de la minería aurífera aluvial 3. Control de la min. ilegaI y saneamiento de la MAPE: Ejes estratégicos

Read More

MERCURIO EN ÁREAS DEGRADADAS POR LA MINERÍA AURÍFERA ALUVIAL EN LA ...

2020.10.29 En cambio, zonas como La Comunidad Nativa de San Jacinto, Comunidad de Kotzimba, Santa Rita y Laberinto, los niveles de Hg fueron 0.01±0.016 mg kg-1DM, mucho más bajo que el bosque con 0.10±0. ...

Read More

¿Cuánto deja la minería en Argentina?

2022.5.26 utilidades. Como contracara el 80,8% de la facturación permaneció fronteras adentro a través de pagos de salarios, compras a proveedores nacionales, impuestos y ganancias de las empresas que no fueron remitidas al exterior. Asimismo, dado el carácter altamente exportador de la gran minería (87,2% del total facturado se exporta)

Read More

Bibliografia minera colonial Hispanoamericana (siglos XV-XIX)

1 La actualización de la Bibliografía minera hispanoamericana (siglos XVI-XIX) ha sido realizada a partir de una recopilación bibliográfica a cargo de las autoras y en el caso de los Andes se basa en la ponencia « Guairas, huacas e inventos : la historiografía de la minería colonial peruana » presentada por Carmen Salazar-Soler en la X Reunión de

Read More

EN la historia económica de la Edad Media, la minería

EN la historia económica de la Edad Media, la minería y la metalurgia forman, por lo regular, un renglón descuidado. Por ejemplo, en la obra de Henri Pirenne, Historia Económica de Euro-pa en la Edad Media, que se ha convertido en uno de los manuales principales de la materia, se dedica a la minería y la metalurgia exactamente me dia página.

Read More

La Minería Urbana. Un análisis desde el ordenamiento

2020.8.7 La Minería Urbana. Origen, concepto, y desarrollo. 2. El Derecho Ambiental y la minería urbana en el contexto del principio del desarrollo sostenible en pos de avanzar a la economía circular. 3. La actividad minera en Cuba. Regulación y desarrollo en el ordenamiento jurídico. – Epílogo. – Bibliografía.

Read More

Escenarios plurales de la expansión minera española del

2023.3.31 En aquest text s'analitzen els factors que expliquen l'expansió minera a Espanya durant el segle XIX i el primer terç del segle XX, situant-los dins del debat al voltant de la repercussió del desenvolupament del sector a l'economia espanyola. A continuació, a partir de l'anàlisi de fonts com les declaracions fiscals de les empreses mineres o el

Read More

La crisis de la minería del Norte Chico, Chile en la primera

La actual región de Coquimbo vivió un complejo proceso que derivó en un estancamiento productivo, iniciado durante el último cuarto del siglo XIX y que se prolongó hasta mediados del siglo XX. El origen de tan prolongado ciclo estuvo radicado en la minería del cobre, la cual quedó expuesta, dadas sus rigideces, a los cambios en el mercado internacional

Read More

EN la historia económica de la Edad Media, la minería

EN la historia económica de la Edad Media, la minería y la metalurgia forman, por lo regular, un renglón descuidado. Por ejemplo, en la obra de Henri Pirenne, Historia Económica de Euro-pa en la Edad Media, que se ha convertido en uno de los manuales principales de la materia, se dedica a la minería y la metalurgia exactamente me dia página.

Read More

Minería y metalurgia antiguas - Casa de Velázquez

En los últimos años, el conocimiento de las minas y de las metalurgias antiguas ha experimentado notables progresos. Este libro, dedicado esencialmente a la Península Ibérica –una de las más grandes regiones productoras de metales de la Antigüedad-, pero que también dedica dos artículos de fondo sobre el Laurión (Grecia) y Rumanía, muestra

Read More

Minería y competitividad Internacional en América Latina

2023.8.31 las reformas mineras de los noventa en la participación y el posicionamiento de la minería de los países de América Latina, precisando, a partir de estos indicadores, el nivel de competitividad internacional que se ha alcanzado, al concluir el primer quinquenio del nuevo siglo. Para estos

Read More

Museo de la Minería del País Vasco - Bizkaias

El patrimonio de la minería evidencia la importancia industrial que tuvo la explotación del hierro, que supuso una transformación del paisaje natural, social y económico. Actualmente en estos montes está impresa la huella de la extracción de mineral a lo largo de la historia. Uno de los ejemplos más claros es la corta de Bodovalle.

Read More