directeur directrice des ventes dequipement minier de chine POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

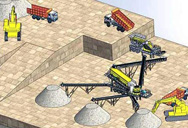

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- v1010 concasseur à percussion horizontale

- shanghai usine de machines concasseur à mâchoires

- petites moyennes grandes roches roches roches

- conception de la machine Indonésie laver en pierre

- Philippines Concasseur Mobile Pour Le Prix

- simmons concasseur à c ne cs 240 vidéo

- Le Minerai De Fer Broyeur A Boulets

- fournitures pour mines et carrières

- structure du broyeur à marteaux

- les coûts estimes pour Afrique concasseur de minerai

- malaisie prix du concasseur à machoires dans rs indiens

- travail de concasseur pieces de concasseurs

- concasseur de pierre importateur jakarta

- Afrique concasseur de pierre ligne de production de l usine

- machine de melange de prix de beton

installation de concassage indien 120 tph

Machines de mélange de béton Fabricants de Chine, Machines de

liste de Machines de mélange de béton fabricants de Chine, accéder aux Machines de mélange de béton fabricants et Machines de mélange de béton fournisseurs de Chine avec efficacité sur fr.Made-in-China

Read More

Machine à béton - CONMACH

1 天前 Les points les plus importants à prendre en compte lors de l’achat d’une machine à béton de qualité sont les suivants : Capacité: Le choix d’une machine adaptée à la taille

Read More

Mélangeur à béton mobile - Équipement de mélange de

2024.1.15 La bétonnière mobile est équipée de pneus, peut se déplacer d'un chantier à l'autre, c'est un choix idéal pour plusieurs projets, cliquez pour la liste de prix !

Read More

Prix Du Mélange De Béton - machines-plant

Le mélange de béton est un mélange uniforme de ciment Portland, de granulats, de sable et d'autres ingrédients approuvés. Pour les travaux de béton en général avec au moins 2 ?

Read More

Centrale à Béton Hzs120 Pour Matériel De Construction

La centrale à béton HZS120 appartient à un équipement de centrale à béton à grande échelle, qui peut produire 120 mètres cubes de béton par heure. Équipement de centrale

Read More

Melange béton à la tonne POINT.P

Melange béton à la tonne de la marque - sur Pointp. Retrait en agence sous 2h. 850 Agences et 150 Showrooms. Paiement sécurisé.

Read More

Mélangeurs à béton - Graco Inc.

5 天之前 Avec la gamme de mélangeurs à béton continus de Graco, vous obtiendrez des résultats homogènes d’un lot à l’autre tout en améliorant votre productivité. Mélangez

Read More

Le mélange béton Comment faire ? A quel prix?

6 天之前 Le premier prix d’un sac de mélange béton est de l’ordre de ~0,10 – 0,13€/kg. Rapporté au m3 de béton, cela représente un tarif supérieur à ~250 €/m3. Le sac de mélange granulat

Read More

Mélanger du béton HORNBACH Suisse

PROJETS Mélanger du béton Guide Mélanger du béton # Fondation # Gros oeuvre rénovation Le béton est au sens premier du terme ce sur quoi reposent de nombreux

Read More

Machines de mélange de béton Fabricants de Chine, Machines de

liste de Machines de mélange de béton fabricants de Chine, accéder aux Machines de mélange de béton fabricants et Machines de mélange de béton fournisseurs de Chine avec efficacité sur fr.Made-in-China ... Machines de mélange de béton Prix. la Machinerie de Construction Fabricants Prix; Machine de Construction Fabricants Prix; le ...

Read More

Malaxeur à béton prix de malaxeur à deux arbres malaxeur

2021.4.15 Le prix du malaxeur à deux arbres horizontaux est à partir de 6.480 dollar US. Ce qui est différent du prix du malaxeur planétaire, prix à partir de 12.600 dollar US. Comme vous le constatez, le prix de nos malaxeurs est vraiment abordable vue la durée de vie et la qualité de nos machines. Cependant il ne faut pas oublier qu’il y a une ...

Read More

Le mélange béton Comment faire ? A quel prix?

6 天之前 Le sac de mélange béton (complet) Le premier prix d’un sac de mélange béton est de l’ordre de ~0,10 – 0,13€/kg. Rapporté au m3 de béton, cela représente un tarif supérieur à ~250 €/m3. Le sac de

Read More

Machine de fabrication de blocs de béton à vendre

Matières premières de la machine de fabrication de blocs de béton. Les matières premières des machines à blocs de béton à vendre sont principalement le ciment, les cendres volantes, les galets, le sable, la gangue, la farine de montagne, le laitier, le clinker de four, les déchets de construction, etc. Sont généralement des agrégats grossiers, des

Read More

Centrale à Béton Hzs120 Pour Matériel De Construction

Bétonnière HZS120, mélange de béton 120 mètres cubes. La centrale à béton HZS120 est une centrale à béton stationnaire à grande échelle avec une capacité de production de 120m³/h. Il adopte le malaxeur à béton forcé à double arbre JS2000, qui a une capacité de mélange élevée, un temps de mélange court et des performances ...

Read More

Faire du Béton Lavé Dosage, Blanc, Prix m2, Gris, Dalle

2024.1.22 Pour un béton lavé, on utilise généralement un dosage de ciment d’environ 350 kg par mètre cube de béton. Sable : Le sable donne de la consistance au mélange. Un ratio courant est d’environ 2 parts de sable pour 1 part de ciment. Graviers : Les graviers ou les cailloux sont importants pour la résistance mécanique du béton.

Read More

fr/conception de mélange de béton avec sable

conception de mélange de béton avec sable concasseur. Prix Concasseur De Pierre: Concasseur beton Concasseur con15m 'Concasseur de béton' 9 prestataires correspondant à votre critère de recherche ont été trouvés.Les messages liés au concasseur à béton » concasseur à sable » La ligne de production de sable artificiel » concasseur à marteaux

Read More

Xfminrui Jzc350 — Mélangeur De Ciment Électrique

Xfminrui Jzc350 — Mélangeur De Ciment Électrique,Meilleure Marque,Pour Le Béton , Find Complete Details about Xfminrui Jzc350 — Mélangeur De Ciment Électrique,Meilleure Marque,Pour Le Béton,Ingco Bétonnière,Meilleure Marque Bétonnière,Électrique En Béton De Ciment Mélangeur from Concrete Mixers Supplier or Manufacturer-Henan Minrui

Read More

Mélanger du béton HORNBACH Suisse

Proportion de mélange du béton universel. Tu mélanges le béton universel dans un rapport de 4:1. C'est-à-dire quatre volumes de sable/gravier et un volume de ciment. En pratique, cela peut ressembler à ceci: 12 pelletées de sable/gravier. 3 pelletées de ciment.

Read More

Calcul pour une dalle en béton Volume (m3), dosage prix

6 天之前 1°) Calcul de la quantité de béton en m³. Pour calculer la quantité de béton de votre dalle, vous devez évaluer son volume. La formule pour un volume est fonction de la forme à mettre en œuvre. Voici un tableau exposant ces différentes formules : Forme. Calcul de surface (en m2) rectangle. longueur x largeur. carré.

Read More

Mélangeur à béton mobile - Équipement de mélange de

2024.1.15 Bétonnière mobile à chargement automatique à vendre. Nous pouvons vous fournir AS-1.2, AS-1.8, AS-2.5, AS-2.6, AS-3.2, AS-3.5, AS-4.0, AS-5.5 et AS-6.5, le modèle le plus chaud en AS-3.5, vous peut vérifier les spécifications ci-dessous. Cette bétonnière à chargement automatique peut charger automatiquement les matières

Read More

Quel est le prix du m3 de béton ? – Tout sur le béton

2024.1.11 Prix du m 3 de béton gâché à la bétonnière ou à la main. Voici le détail du calcul du prix du béton au m3 réalisé à la bétonnière ou à la main. Si l’on considère les coûts de matériaux suivants : Sable en sac

Read More

Mélange de béton mobile à chargement automatique - Machine ...

En général, la capacité est plus grande, le prix du mélange de béton mobile à chargement automatique est plus cher. La plupart des clients sont préoccupés par les prix. Ainsi, j'ai listé ses gammes de prix. Gammes de prix des mélangeurs à chargement automatique. Prix AS-1.8 et AS-2.6 : 13000 21000 $ ~ XNUMX XNUMX $

Read More

Machine de pompe à béton à vendre - Machine de coulée de

6 天之前 Machine de pompe à béton à vendre-classée par principe de fonctionnement. Nous avons une bétonnière avec pompe et pompe à béton de type remorque à vendre. La seule différence est de savoir si a une bétonnière. La pompe à béton avec malaxeur se compose d'un bétonnière et une pompe à béton, afin qu'elle puisse produire du béton ...

Read More

Béton rapide sans malaxage, pratique mais cher à l'usage

2018.7.13 Plusieurs marques de béton rapide sans malaxage. PRB propose le Béton express sans malaxage prise rapide à 7€50 environ les 20kg. VPI propose le Speed Béton sans malaxage à 9€ environ les 25kg. Weber propose le Micro béton de maçonnerie ultra-rapide sans malaxage pour scellements courants – Sac de 25kg au prix de 10€ en

Read More

Achetez des machine de mélange concret exquis avec des

machine de mélange concret avec des fonctionnalités exceptionnelles sont vendus sur Alibaba, les principaux fabricants, distributeurs et vendeurs sont inscrits sur le site. Par conséquent, les acheteurs obtiennent. machine de mélange concret avec des conceptions et des styles impeccables qui améliorent la fabrication et le rendement du ...

Read More

Soldes Mélange à béton Leroy Merlin

Mélange en big-bag 0.25m3. Mélange 0/2 en big-bag 750 Kg. Mélange en big-bag 500 Kg. Soldes Mélange à béton - Marques, Stock Livraison rapide chez Leroy Merlin. Un grand choix de produits aux meilleurs prix.

Read More

Comment calculer le dosage du béton pour 1m3? - Artisan Beton

2024.1.18 Mélanger le béton et obtenir le bon mélange est essentiel pour un travail durable. Le calcul du dosage du béton pour 1m3, vous aide à déterminer exactement le type de béton dont vous avez besoin pour votre projet. Un moyen simple de mesurer les dosages dans le béton consiste à procéder comme suit: 1 portion de ciment, 2 portions de ...

Read More

1 m3 de béton: Dosage, Calcul, Fabrication - Travaux Béton

6 天之前 Fabriquer vous-même votre béton en mélangeant du sable, du ciment, du gravier et de l’eau dans une bétonnière. Vous pouvez également utiliser un sac pré-mélangé. Cette option est tout à fait réalisable en dessous de 1 m3, au delà, elle devient fastidieuse car le rendement d’une bétonnière est faible. Devis béton livré dès 0 ...

Read More

Calcul du béton volume, quantité (m3), dosage

6 天之前 Le calcul de volume du béton. Dans un projet de construction, il est très important de calculer la juste quantité de béton. Celle-ci s’exprime en m 3, ce qui correspond à une unité de volume (1 m 3 = 1 000 L).. Nous allons vous expliquer comment calculer un volume de béton dans plusieurs cas de figure : la dalle, la fondation, le mur banché, l’escalier et

Read More

Prix de la machine de fabrication de briques - Le prix le plus ...

Mais en fait, la liste de prix des machines à briques est variable. Différents types, capacités, configuration, destination et méthode d'expédition affecteront le prix de la machine à briques. Donc, si vous voulez connaître le prix exact, vous devez choisir le bon moment, et nous parler en détail de votre projet.

Read More

Machine de Mélange prix, obtenir la dernière Machine de

Machine de Mélange prix, avec plus de 664284 Machine de Mélange produits. Obtenez 2023 prix d'usine, prix Fob, prix de gros, et Machine de Mélange liste de prix sur Made-in-China.

Read More

Machine de Béton, Machine de Béton en Chine catalogue de

Liste de produits de Machine de Béton et produits de Machine de Béton made in China pour aider les acheteurs francophones à trouver les protuits de Machine de Béton de la Chine ... machinerie de construction 2012 Année Zoomlion 47m de la pompe Beton le pompage de béton utilisé Pompe à ... Prix FOB de Référence: 175 000,00-200 000,00 ...

Read More

Beton : melange beton, melange sable gravier Castorama

Béton. Le béton tout comme le mortier sont indispensables pour une bonne maçonnerie. Ce mélange de ciment, sable et gravier, une fois mélangé avec de l'eau, se solidifie pour obtenir le béton correspondant à l'usage attendu. Il existe différents types de béton, en fonction des performances recherchées : béton fibré, béton ...

Read More

Machine a Brique Prix Manuelle Et Automatique - Mussan Machine

2023.3.10 Les prix des machines à briques de béton varient en fonction de plusieurs facteurs tels que la capacité de production, la qualité de la machine, la technologie utilisée et les fonctionnalités de la machine. En général, les machines à briques manuelles sont moins chères que les machines semi-automatiques ou entièrement automatiques.

Read More

Le camion centrale à béton mobile – Tout sur le béton

2024.1.11 A la sortie de la vis, on obtient du béton frais prêt à l’emploi. Un camion centrale mobile (camion qui fabrique le beton sur place). Selon le matériel, le béton peut être déchargé à plusieurs mètres de distance (entre 5 et 7m selon modèle) depuis l’arrière du camion grâce à des rallonges de goulottes ou bien des bandes ...

Read More

Centrale a beton a vendre - MADE IN TURQUIE Yorkam Group

2024.1.7 Capacités de production entre 30 m3 et 240 m3 par heure. Pour commander : Appelez +90 505 130 2931 (WhatsApp) ou envoyez un email info@yorkamgroup. Centrale beton Version 30 m3 par heure. Centrale beton Version 60 m3 par heure. Centrale beton Version 120 m3 par heure. Centrale beton Version 240

Read More

Mélanger et Teinture Collomix colortec - test og

La machine de mise à la teinte Collomix TINTA peut être parfaitement combinée avec les shakers et mélangeurs gyroscopiques Collomix. Consultant et service. Pour définir les paramètres de produits, les exigences techniques et le résultat souhaité, nous offrons à nos clients des « services de consultation » individuels. ...

Read More

Camion ou bétonnière: lequel choisir? Prix, volume m3

5 天之前 Le prix d’un béton fabriqué sur chantier est de 200€/m3 alors que le prix d’un camion toupie est de 100-130€/m3. En apparence, le prix du camion toupie est plus intéressant. Mais il ne faut pas s’y méprendre ! La tarification dépend fortement du

Read More

Le calcul du dosage beton - Tout sur le béton

2024.1.12 Dosage beton fondation : 1 volume de ciment, 2,5 volumes de sable, 3,5 volumes de gravillons et un demi volume d’eau. Après, il faut savoir que la fabrication à la bétonnière ou à la main (à l’aide de pelles de mélange), gâchée par gâchée, est très longue, laborieuse et pénible. Le rendement est faible.

Read More

>> Next:Laveur De Sable Avec Convoyeur à Bandes