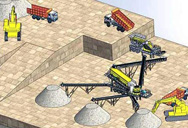

machine de meuleuse Indonésie rouleaux raymond POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- fournisseur de convoyeur Indonésie bande de concasseur en Nouvelle Caldonia

- concasseur à cône 5 1 2

- concasseur propriete de minerai de fer

- jaw crusher fabricants mumbai

- usine scenario de concasseur

- pe 400 by 600 single toggle jaw crusher specifications

- Scie occasion de broyage de la machine de broyage de

- les tamis pour faience

- rapport de projet de la machine de broyeur de pierres gratuitement

- Principe De Fonctionnement Pour Les Concasseurs

- Équipements utilisés pour la minning

- ampere mobile de depistage amp nz concassage

- premier exportateur mondial de minerai de chromite

- Lignite Bâtiment Du Concasseur Les Photos De Concasseur

- concasseur à cône discuté

installation de concassage indien 120 tph

Concasseurs à cône pour votre concassage secondaire

5 天之前 Un concasseur à cône peut concasser une grande variété de roches, dont la dureté varie de moyenne à dure. Le fonctionnement d’un concasseur à cône est similaire

Read More

Concasseurs à cône - Metso

Les concasseurs à cône sont des matériels de concassage appréciés dans la production de granulats, l'exploitation minière et les applications de recyclage. Ils sont habituellement

Read More

Concasseurs mobiles à cône Caterpillar QS441

Le concasseur mobile à cône QS441 Sandvik est équipé du cône giratoire CS440. Doté de fonctions, telles que la caméra à distance, le détecteur

Read More

Concasseurs à cône Série Nordberg® GP™ - Metso

Les concasseurs à cône de la gamme Nordberg® GP™ peuvent être adaptés à toutes les exigences spécifiques de production, à travers des ajustements tels que la modification

Read More

Concassage hautes performances Concasseurs à cône

2023.1.20 Concasseurs à cône Nordberg Série HP 3. Production éprouvée et prévisible. Les concasseurs à cône Série HP ofrent une capacité, une taille de produit

Read More

Concasseurs mobiles à cône Caterpillar QH332

Concasseurs mobiles à cône Sandvik QH332. Le concasseur à cône QH332 est particulièrement productif pour vous permettre de travailler dans une large gamme d’applications. Le QH332 bénéficie des techniques de

Read More

Concasseurs mobiles à cône Caterpillar QS332

Les concasseurs mobiles à cône Sandvik QS332 sont conçus pour répondre à toutes vos exigences de qualité de produit et vous garantir une productivité maximale, sur plusieurs cycles de vies. Grâce au

Read More

Concasseurs pour vos besoins opérationnels en concassage

2024.1.24 À cône : Ils sont équipés d’un cône mobile qui tourne pour concasser le matériau. Ils sont souvent utilisés pour concasser des matériaux durs et abrasifs tels que

Read More

Concasseur à cône, Unité de concassage à cône

Un concasseur à cône est une machine de broyage utilisée pour briser des blocs de matière minérale en blocs de taille inférieure de granulométrie déterminée. Le concasseur à cône écrase les blocs entre deux surfaces,

Read More

Concasseur à cône mobile C-1545 Concasseur sur chenilles

2024.1.24 Concasseur à cône Le C-1545 de Finlay® est un concasseur giratoire puissant de grande capacité fournissant un rendement élevé constant et un produit d’une

Read More

Nordberg® HP200e™ Concasseur à cône - Metso

Le nouveau concasseur à cône Nordberg® HP200e™ offre de meilleures performances et une meilleure disponibilité de manière plus durable. Il offre des performances améliorées, une maintenance plus simple et plus

Read More

Le concasseur, bien connaître son fonctionnement pour mieux

2021.9.24 Le concasseur est une machine grandement utilisée dans de nombreux domaines, comme l’industrie de l’exploitation minière, le recyclage et la construction. En principe, elle sert à réduire la taille des roches, la production de gravillon de toutes tailles. Elle a également la capacité de broyer le métal dans un processus de traitement pour le

Read More

Concasseurs à mâchoires Série Nordberg® C™ - Metso

Fiabilité sans compromis. Les concasseurs à mâchoires Série Nordberg® C™ s'appuient sur une construction du bâti goupillée et boulonnée, sans soudure, qui offre une excellente résistance aux contraintes. Tous les composants du bâti sont moulés dans un alliage spécifiquement développé par Metso pour ses concasseurs à mâchoires.

Read More

Concasseurs mobiles - Metso

Concasseurs à cône mobiles. Les concasseurs à cône mobiles sont traditionnellement utilisés comme concasseurs secondaires, tertiaires et quaternaires. Toutefois, si la granulométrie du matériau traité est suffisamment petite, ils peuvent également fonctionner à la première étape de réduction. Concasseurs à percussion mobiles

Read More

Les différents types de concasseurs suivant vos besoins

2021.9.24 Un concasseur à cône est conçu pour concasser des matériaux généralement de 100mm à 200mm. Plusieurs sont les avantages d’utiliser ce type de concasseurs. À titre d’exemple, il possède un réglage facile : il suffit de tourner le bol pour modifier la position de la machine. Ce concasseur est également doté d’un système qui

Read More

Concasseurs mobiles à cône Caterpillar QS332 Bergerat

Les concasseurs mobiles à cône Sandvik QS332 sont conçus pour répondre à toutes vos exigences de qualité de produit et vous garantir une productivité maximale, sur plusieurs cycles de vies. Grâce au concasseur Sandvik CS430, vous bénéficiez des techniques de concassage de formes cubiques (CSC), vous permettant de produire un matériau de

Read More

MR 110i EVO2 Concasseurs mobiles à percussion

Propriétés. Le concasseur mobile à percussion MOBIREX MR 110i EVO2 est très polyvalent et produit un granulat de qualité supérieure. Avec un gueulard de 1 100 mm et un grand nombre de spécificités techniques, il atteint un débit remarquable avec le meilleur rendement possible. Grâce à sa structure compacte, la machine est facile à ...

Read More

Analyse de la taille et de la part du marché mondial des concasseurs à ...

Par exemple, le concasseur à cône Nordberg HP900 de Metso est livré avec un nouveau système de lubrification, une cinématique améliorée, un point de pivot surélevé et une puissance accrue pour offrir une augmentation de 15% de sa capacité. Laugmentation de la taille permet daccroître la production et la production dans les industries ...

Read More

Concasseurs - Pour tous vos besoins de réduction - Metso

Pour tous vos besoins de réduction. Les broyeurs et concasseurs sont des machines destinées à réduire la granulométrie des roches et pierres dans les opérations de production de granulats, de recyclage des matériaux de construction et d'exploitation minière. Metso conçoit et fabrique des concasseurs depuis plus de 100 ans.

Read More

TOP 5 Fabricant de concasseurs à cône dans le monde

2019.4.25 Il existe de nombreux bons fabricants de concasseurs à cône dans le monde. À l'heure actuelle, laissez-moi vous présenter les 5 principaux fournisseurs de concasseurs à cône et fabriqués. Ce classement est basé sur la tendance de Google et notre expérience (nous travaillons dans la fabrication de pièces d'usure pour

Read More

Concasseurs à Cône - MEKA

Les concasseurs à cône MEKA sont le meilleur choix en tant que concasseurs secondaires en combinaison avec un concasseur à mâchoire. et un concasseur giratoire primaire dans la troisième ou quatrième phase de processus de concassage. Lors d'un besoin d'un concasseur pour la production d'agrégats, nos concasseurs à cône sont les plus ...

Read More

Concasseurs à cône - Metso

La gamme de concasseurs à cône Nordberg® HP™ est la plus populaire au monde, avec plus de 10 000 machines vendues à l'international. Les concasseurs à cône Nordberg® HP™ offrent d'excellentes performances et un broyage fiable pour toutes les applications de production d'exploitation de carrière et d'exploitation minière.

Read More

Tout savoir sur les concasseurs Guide complet

Un concasseur à cône peut se définir comme un concasseur giratoire amélioré. Il se diffère cependant de ce dernier par son axe de concassage supporté, et non suspendu. Ce qui permet d'améliorer la capacité de la

Read More

Concasseur à cône 1000 Maxtrak Powerscreen

2024.1.21 Le concasseur de roches mobile 1000 Maxtrak de Powerscreen® hautement performant a été conçu pour les applications à alimentation directe sans pré-criblage sur roches propres. Au cœur de cette installation se trouve le concasseur à cône Automax®, qui assure une excellente réduction et une bonne cubicité du produit dans la

Read More

10 Facteurs à prendre en compte lors du choix d'un

2022.5.24 Lors du concassage de la pierre tendre, le concasseur à cône, le concasseur à percussion ou le concasseur à marteaux peuvent être utilisés directement. 1.Indicateurs économiques Les dépenses préalables sont les investissements nécessaires et préalables pour soutenir le fonctionnement normal de la machine.

Read More

Pièces pour concasseur à cône - Metso

La fiabilité des pièces de rechange et d'usure du concasseur à cône permettent une production stable sans temps d'arrêt imprévu. Nous proposons une large gamme de pièces de rechange pour concasseurs à cône pour les modèles Metso, Nordberg® et Symons™, ainsi que de nombreux concasseurs fabriqués par d'autres fabricants.

Read More

MEMOIRE DE FIN D’ETUDE

2022.9.25 de sortie ou avec concasseur à barre d’impact. [10]. ..... 35 Figure 3. 4: Ancien modèle de concassage à deux étages en une seule passe avec concasseur à mâchoires et concasseur à marteaux rotatifs et à double rotors avec grille de sortie.

Read More

QA: Logiciel de simulation Bruno pour l’optimisation de la

2021.6.11 Toutefois, tous partagent un but commun : être capable de produire exactement ce que veulent leurs clients. Nous avons discuté avec notre expert Saku Pursio, ingénieur en charge du développement du logiciel Bruno, pour comprendre comment notre logiciel de simulation peut aider les clients à choisir l’équipement approprié.

Read More

Pièces pour concasseurs - Metso

Des performances de concassage optimales. Pièces pour les concasseurs giratoires, à mâchoires, à cône et à percussion pour les concasseurs Metso et non-Metso. Conçues pour s'adapter et fonctionner au maximum de leurs performances, ces pièces aident votre concasseur à performer.

Read More

Concasseur à cône, Unité de concassage à cône

Le concasseur à cône écrase les blocs entre deux surfaces, l'une concave et fixe et l'autre conique et mobile, toutes deux recouvertes d'un blindage résistant à l'usure. Les blocs entrent par le sommet et se coincent entre les deux surfaces. Ils sont écrasés par le mouvement excentré du cône mobile et se brisent en morceaux plus petits.

Read More

Concasseurs godet broyeur, terrassement,

Concasseurs. 348 produits trouvés. Les concasseurs trouvent des utilisations dans les carrières, les chantiers de construction et les mines. Ils servent principalement à : Écraser les pierres naturelles, les roches, les

Read More

Concasseurs pour vos besoins opérationnels en concassage

2024.1.24 Voghel vous offre une vaste gamme de concasseurs à cône, à mâchoire et à impact de Terex-Finlay et Cedarapids mobiles ou stationnaires. +1(514) 990-6636 [email protected] Facebook; Instagram; Linkedin; YouTube; ... Concasseur à cône C-1550+ Concasseur à mâchoire J-1160 (2021)

Read More

MOBILE PROCESSING - Wirtgen Group

5 天之前 Concasseur à cône : Réglage du concasseur à cône, voir page 188, chap. « Mise en place du concasseur à cône » , selon la courbe de grain souhaitée la continuité du flux des matériaux le taux de chargement optimal du concasseur à cône Dans l'exemple sélectionné : Outil de concassage : Standard moyen / grossier, 18 % Mn CSS ...

Read More

Concasseur à cône à vendre - Équipement de concassage

Caractéristiques du concasseur à cône de roche multicylindre. 1. Structure spéciale et bon effet de broyage. La combinaison d'un type de chambre de concassage haute performance et d'une fréquence de concassage élevée améliore considérablement la capacité de traitement du concasseur à cône à vendre et, en raison du principe de concassage par

Read More

Concasseur de Pierre, Concasseur de Pierre en Chine

Liste de produits de Concasseur de Pierre et produits de Concasseur de Pierre made in China pour aider les acheteurs francophones à trouver les protuits de ...

Read More

Technologie de concassage et de criblage portable - Terex

2020.2.28 les plus évoluées – et notamment le module de criblage à cône en circuit fermé CRC380XHLS, avec son système de crible HLS pour une efficacité maximisée. Tous nos concasseurs à cône sont conçus pour une productivité élevée et une portabilité simplifiée – de manière à maximiser votre équipement et votre investissement.

Read More

La meilleure adaptation à l'application Concasseurs à

2023.5.29 production d'un concasseur, tels que la longueur de la course, la capacité et la qualité, sont tous facilement réglés en faisant tourner la bague excentrique à l'intérieur du concasseur. Les concasseurs à cône GP utilisent le système d'automatisation IC50C pour des conditions de fonctionnement optimales, un contrôle complet de l'étape de

Read More

Un guide complet des pièces de concasseur à cône - Qiming

5 天之前 Pour rendre cela possible, un concasseur à cône se compose de plusieurs parties, chacune remplissant une fonction spécifique. Ces pièces de concasseur à cône comprennent : Ensembles bol, revêtement de bol et trémie. Ensembles tête, manteau et cône d'alimentation. Assemblage des manches.

Read More

Concasseurs à cône Série Nordberg® HP™ - Metso

Les concasseurs à cône Série Nordberg® HP™ présentent une combinaison unique de vitesse, de portée, de forces de concassage et de conception de cavité. Cette combinaison est réputée pour offrir une capacité plus élevée et une qualité supérieure du produit final dans toutes les applications secondaires, tertiaires et quaternaires.

Read More

Sélection des chambres de broyage pour broyeurs à cône

2021.6.9 Sélection des chambres de broyage. De nombreux facteurs doivent être pris en compte dans la sélection d'un profil de chambre de broyeur à cône le plus adapté à vos besoins. Un profil de mâchoires inadapté pourra se traduire par des temps d'arrêt prolongés du fait de l'usure excessive des mâchoires, une efficacité moindre et, dans ...

Read More