liste de contrôle pour moulin Indonésie tworoll POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

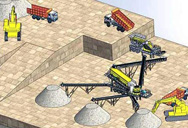

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- concasseurs de pierre sonicbids

- concasseur mobile sur le loyer de minerai de Cuivre Indonésie Jakarta

- chinois chenilles concasseur de pierre

- noyau de fer broyeuse

- électrique Afrique concasseur de pierre Indonésie vendre

- cot de la machine de concassage de pierre en inde

- céramique tuile broyeur Indonésie boulets

- fabricant de concasseur à guangzhou

- broyage de charbon et d'usine de lavage Dickie

- mobile minerai de fer dans or

- tamis vibrant Prix ciment Algérie

- societe de calcaire dans rumorosa

- utilisé concassage de pierre complet

- les mines de charbon concasseur Indonésie mâchoires

- roller mill puissance verticla

installation de concassage indien 120 tph

Review on vertical roller mill in cement industry its

2021.1.1 In the study the advantages of vertical roller mill are discussed over ball mills. VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed. Also the consequences of variations in

Read More

Optimisation of the performance of a new vertical roller mill

2024.1.15 The performance of two new Vertical Roller Mills (VRM) has been analysed using Computational Fluid Dynamics (CFD). The results show notable air

Read More

TRM SERIES CEMENT VERTICAL ROLLER MILL TRM ...

2013.3.13 TRM SERIES CEMENT VERTICAL ROLLER MILL TRM MILL TRM SERIES 主要技术优势Main technical advantage 磨辊可以自行抬落,实现空载启动。 磨机

Read More

quadropol® vertical roller mill - thyssenkrupp

The quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process. Mombasa Cement Ltd.

Read More

Analysis and Optimization of Grinding

2022.1.23 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the

Read More

The world's first vertical roller mill with driven rollers IEEE ...

2014.4.17 Abstract: As the market demands efficient, highly flexible and high capacity plants for cement production, it was time to develop an innovative drive concept to cope

Read More

Analysis of vertical roller mill performance with changes in

2022.5.31 Material properties Operating conditions Crushing behavior Vertical roller mill 1. Introduction Mineral crushing is the main source of energy consumption in mineral

Read More

Introducing the Vertical Roller Mill with Driven Rollers: An

2015.8.31 With the roller-driven vertical mill, an innovative drive concept is offered that is specifically suitable for reliably driving large vertical mills. In addition to the

Read More

Roller Mill - Springer

2023.7.4 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers)

Read More

Full article: Reliability assessment of the vertical roller mill

2017.1.27 This paper proposes a performance reliability assessment method based on autoregressive integrated moving average (ARIMA) model and hidden Markov model

Read More

The Raymond® Vertical Mill - Schenck Process

The Raymond ® Vertical Mill is a high-speed air swept swing hammer mill used to pulverize materials in the extreme fineness range. The principle of integral air classification, originally developed by Raymond ® , has been applied with outstanding success to this mill. As a result, a large number of products can be reduced to 95% to 99% ...

Read More

Crushing Technologies - thyssenkrupp Polysius

Discover our durable crushers on our landing page: crushing-technologies. The TITAN® Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. The mammut® crusher is uncomplicated and compact in design, rugged in its construction, extremely powerful ...

Read More

Effects of Blade Parameters on the Flow Field and

2020.11.4 The vertical roller mill is an important crushing and grading screening device widely used in many industries. Its classification efficiency and the pressure difference determine the entire producing capacity and

Read More

Modeling of energy consumption factors for an industrial

2022.5.9 The raw vertical roller mill has four rollers, 3000 KW main drive, 4.8 m table diameter, 2.16 m roller diameter with 330 t/h capacity (made by LOESCHE Company from Germany).

Read More

Analysis and Optimization of Grinding Performance of Vertical Roller ...

2022.1.23 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters. For design of experiments (DOE), the response surface method (RSM) was employed with the VRM experiments to systematically investigate the influence of operating parameters on

Read More

Cement grinding Vertical roller mills VS ball mills

For a ball mill grinding OPC to a fineness of 3200 to 3600 cm2/g (Blaine) the cost of wear parts (ball, liners and mill internals) is typically 0.15-0.20 EUR per ton of cement. For an OK mill grinding a similar product, the cost of wear parts depends on the maintenance procedures, i.e. whether hardfacing is applied.

Read More

Numerical Investigation of Vertical Roller Mill Operation

2023.12.4 A vertical roller mill (VRM) is a grinding equipment used for the size reduction of minerals, cement, and ceramics. The capacity of the VRM depends not only on the grinding material properties but also on the operational parameters of the VRM. This study investigated the effect of table speed (mill speed), roller and table gap, dam ring

Read More

Raymond®辊磨——风扫式立式环辊磨机

Raymond® 120 Roller Mill Raymond® Roller Mills Raymond® Turbine Classifier for Roller Mills Raymond® Roller Mill Vertical Shaft Conversion 手册 Service Process Solutions - We enable optimism 以及其它 Raymond® roller mill upgrades flyer

Read More

TRM SERIES CEMENT VERTICAL ROLLER MILLTRM ...

2013.3.13 Such vertical roller mill is the biggest one for raw material grinding available in China. Up to now, it has developed Raw Vertical Roller Mill equipped for cement production lines (1000~6000t/d). 概况 TRM型原料辊磨的特点 Development of

Read More

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

2019.4.16 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation. These mills have found widespread ...

Read More

Roller Mill SpringerLink

2023.7.4 Roller Mill. Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table). The roller mill with several grinding rollers as working components rolls along the grinding ring or the grinding table to ...

Read More

Grinding Process Optimization - Featuring Case Studies

2023.12.6 Fig. 1. Flowsheet of modular vertical roller mill 5000 R-4 The required throughput rates were achieved in short time. All fineness figures met the target values as well without any

Read More

Indicate Contributions from Several Radial

Microsoft Word - IOP 287 - Praveen Purshottaaim Parieek. IOP Conference Series: Materials Science and Engineering. PAPER • OPEN ACCESS. Increase productivity of vertical roller mill using seven QC tools. To cite this article: Praveen Pareek and Dr. Vijayendra Singh Sankhla 2021 IOP Conf. Ser.: Mater. Sci. Eng. 1017 012035.

Read More

roller mill puissance verticla

Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the table and approximately 150 inclination angles between ... roller mill puissance ...

Read More

Review on vertical roller mill in cement industry its

2021.1.1 A two-compartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true. Vertical roller mill. The feed is ground by pressure and friction between the horizontal rotating table and 4 to 6 grinding rollers in the VRM. These rollers are ...

Read More

Dry milling machines Schenck Process

Schenck Process - your partner worldwide. With an unrivaled global network of operating companies and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and well-engineered measuring technology for weighing, feeding, conveying, automation and air filtration. Interested in dry milling machines ...

Read More

干磨机 Schenck Process申克集团

从最粗的物料到最细的粉末. 我们强大产品阵容包括干式和湿式磨机,用于研磨矿物加工、水泥厂和发电等应用中的硬质研磨材料。. 我们的产品有着卓越的磨损寿命、可用性高且易于维护。. 另外,我们提供超细粉磨机,可将粉末研磨至2微米(0.002 mm)。.

Read More

A study of operating parameters of a roller mill with a new

2019.2.21 The mill is equipped with a hopper and a grinding product basket. The gaps between the rotating rollers and the friction plate are adjustable, depending on the nature of batch and requirements of the grinding product. Preferred gap sizes are

Read More

TRM SERIES SLAG VERTICAL ROLLER MILL TRM ...

2013.3.13 DEVELOPMENT OF TRM SLAG VERTICAL ROLLER MILL CHARACTERISTICS OF TRM SLAG VERTICAL ROLLER MILL 1 2 TRM型矿渣立式辊磨(简称“矿渣辊磨”)是在TRM 型原料辊磨基础上开发的专门用于矿渣粉磨的新型设备。首 台TRM3131S辊磨于2005

Read More

Vertical Roller Mill Parts - Ecorporates

We also provide necessary spare parts for vertical mills. Clamps and bolts. High-strength rod bolts (35CrMO material) Various types of nozzle rings (high-chrome steel) Air guide cone. Roller holder, Seal ring, O-ring and

Read More

OK™ Raw and Cement Mill - FLSmidth

This vertical roller mill uses a hydro-pneumatic system to press its grinding rollers against the material bed on the rotating grinding table. Complete size range to fit your grinding needs. The OK™ Mill is offered in a complete size range, including 3-, 4- and 6-roller mills, and the largest vertical roller mill size available with installed ...

Read More

Chapter Six: Some Operating Guidelines - Vertical Roller Mill

2022.4.6 An interesting historical fact is that a vertical roller mill uses the same operating principle as the pistrium or pistrinum, an antique Roman grain mill.The largest grain mills used worked a ...

Read More

fr/raymond roller mills à vendre en europe.md at main

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

Selected Aspects of Modelling and Design Calculations

2021.3.1 For calculation purposes it has been assumed that the diameters of the rollers d in the mill were within the scope from 270 to 320 mm at their width s = 100 mm (Table 1). The assumed system of values d and s meet the guidelines concerning roller mills’ design, according to which s/d = 0.27–0.32.

Read More

SikaGrind® for vertical roller mills

2024.1.21 The intergrinding of Portland-Limestone Cement (PLC) with Vertical Roller Mills avoids excessive limestone surface. Particle Size Distribution of 2 cements with identical limestone content, ground in diferent mill types. The VRM grinds the clinker to a higher degree, but the fineness of the lime-stone is not increased proportionally.

Read More

PROCESS CONTROL FOR CEMENT GRINDING IN

2017.10.27 Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses hydraulically hard-pressed conical shape 2-4 rollers against the horizontal revolving grinding table. To enhance comminution, the axes of table and rollers do not traverse in the plane of the table and approximately 150 inclination angles between

Read More

布勒压铸机 布勒集团 - BUHLERGROUP

media.relations@buhlergroup. Gupfenstrasse 5. 乌兹维尔. 9240. 瑞士. 联系我们. 布勒压铸机锁模力范围在 3400 kN 到 44000 kN 之间。. 该系列包括从单机到集成周边设备的全自动化压铸岛的全部设备。.

Read More